DIN41612 connector crimping method for flat cables and its application in industrial fields

Release time:

2025-06-17

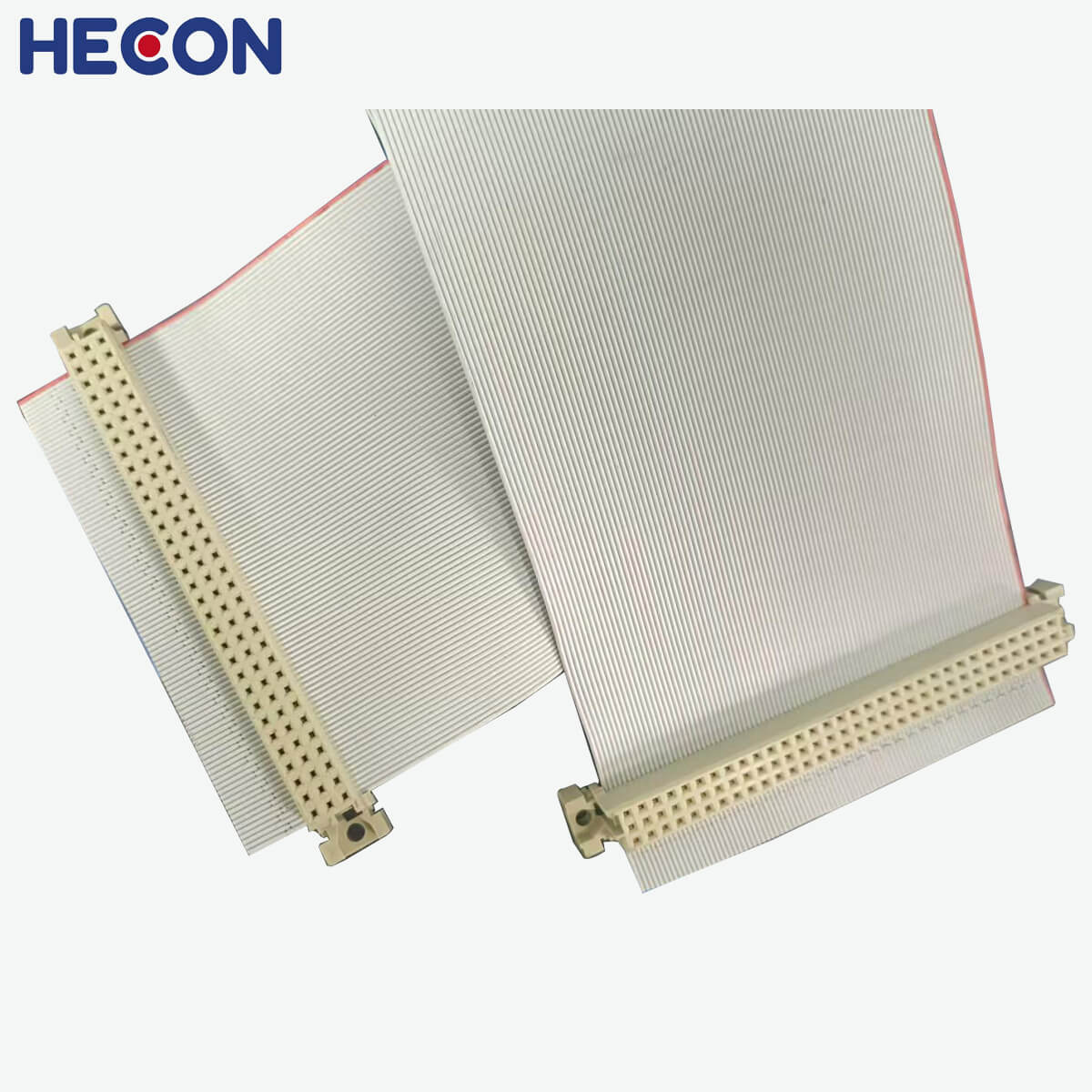

What is a DIN41612 Connector IDC Type 96Pin crimping flat cable?

DIN41612 Connector IDC Type 96Pin crimping flat cable and its importance in industrial equipment

The DIN41612 Connector IDC Type 96Pin crimping flat cable connects electronic boards in industrial and rack-based equipment. This connector uses a high-density pin layout to carry many signals in a small space. Industry reports show that factories and automation systems need reliable, compact connectors to keep machines running with fewer breakdowns. IDC and crimping methods both join wires to connectors, but each offers unique benefits. Standardized connectors help different machines work together and make repairs easier.

Key Takeaways

The DIN41612 Connector IDC Type 96Pin offers a compact, standardized design with 96 pins arranged in three rows, enabling high-density and reliable connections in industrial equipment.

IDC termination saves time by pressing wires into connectors without stripping insulation, making it ideal for mass production, while crimping provides stronger mechanical connections for special needs.

This connector works well in harsh industrial environments thanks to its resistance to temperature changes, vibration, moisture, and corrosion, ensuring long-lasting performance.

It supports high-quality signal transmission by reducing electrical noise and preventing oxidation, which helps machines run smoothly and avoid errors.

Following proper assembly techniques and industry standards ensures safe, compatible, and durable connections that reduce downtime and simplify maintenance.

DIN41612 Connector IDC Type 96Pin crimping flat cable

Structure and Design

The DIN41612 Connector IDC Type 96Pin crimping flat cable stands out for its standardized design. Engineers use this connector in many industrial systems because it supports high-density connections. The connector has 96 pins arranged in three rows, labeled a, b, and c. Each pin sits on a grid with a 2.54 mm (0.1 inch) pitch. This layout allows the connector to fit many signals into a small space.

The triple-row design helps organize connections and reduces wiring errors. Standardization ensures that products from different manufacturers can work together.

The table below shows key features of the DIN41612 Connector IDC Type 96Pin crimping flat cable:

| Feature | Description |

|---|---|

| Pin Count | 96 pins arranged in three rows labeled a, b, and c |

| Grid Pitch | Standardized 0.1 inch (2.54 mm) spacing |

| Current Rating | Typically 1.5A to 2A per pin, with some hybrid configurations up to 5.6A or 15A |

| Voltage Rating | Up to 500V |

| Termination Method | IDC type with crimping termination |

| Standard Compliance | IEC 60603-2 and EN 60603-2 standards ensuring intermateability and reliability |

| Connector Types | Multiple types including IDC, with options for selective contact loading and plating |

| Durability and Quality | Controlled insertion/removal forces, three durability grades, continuous quality assurance |

| Application Areas | Rack-based telecom, computing, industrial automation, military/aerospace, test and measurement |

| Intermateability | Fully intermateable with compliant products from multiple manufacturers |

This connector supports a current rating of 1.5A to 2A per pin, and some versions can handle even higher currents. The voltage rating can reach up to 500V. The connector meets IEC 60603-2 and EN 60603-2 standards, which means it works reliably in many environments. Manufacturers test these connectors for durability and quality, so they last through many cycles of use.

IDC vs. Crimping

The DIN41612 Connector IDC Type 96Pin crimping flat cable uses two main wire termination methods: IDC (Insulation Displacement Contact) and crimping. Each method has unique features and benefits.

IDC connectors do not require wire stripping. Installers can press the wire directly into the connector, which saves time and reduces labor costs.

IDC connections use moderate pressure to pierce the wire insulation. This process creates a secure, gastight metal-to-metal contact. The result is a reliable connection that resists oxidation.

IDC mass termination works well for large-scale manufacturing. The process is fast and cost-effective, especially when using the right tools.

IDC connections tolerate vibration, temperature changes, and moisture. Many telecom and industrial systems use IDC for these reasons.

Crimping requires stripping the wire and using a crimping tool to attach the connector. This method needs more skill and careful technique.

Properly crimped connections are very strong. They work well in applications that need high mechanical strength.

Crimping is best for discrete wire sizes and special cases where extra durability is important.

Crimping takes more time and may cost more in labor and tooling.

Tip: IDC is the preferred choice for mass production and environments where speed and reliability matter most. Crimping suits projects that need extra mechanical strength or use special wire types.

Both IDC and crimping methods help the DIN41612 Connector IDC Type 96Pin crimping flat cable deliver reliable performance in industrial equipment. The choice depends on the application, required strength, and production scale.

Industrial Applications

Board-to-Board and Backplane Use

Many industrial systems use board-to-board and backplane connections to link different circuit boards. The DIN41612 Connector IDC Type 96Pin crimping flat cable helps engineers build these connections in a compact and organized way. This connector fits into rack-based equipment, such as servers, test instruments, and control panels. The triple-row, 96-pin layout allows for high-density signal transmission between boards.

Note: The standardized 2.54 mm pitch and triple-row design help reduce wiring mistakes and make repairs easier.

A table below shows important characteristics that support its use in these applications:

| Characteristic | Value / Description |

|---|---|

| Current loadability per contact | 1.5 A at +20 °C, 1.0 A at +70 °C, 0.5 A at +100 °C |

| Plugging frequency | Pin Strip: 200 cycles; Socket Strip: 50 cycles |

| Temperature range | -55 °C to +125 °C |

| Flammability rating | UL 94-VO (self-extinguishing after 10 seconds) |

| Standards compliance | DIN 41 651, DIN 41 611, IEC, CECC, VDE, UL |

These features allow the connector to work in harsh environments and support frequent connections and disconnections. The connector’s design also ensures compatibility with many types of industrial equipment.

Automation and Control Systems

Automation and control systems need reliable and fast connections for sensors, controllers, and actuators. The DIN41612 Connector IDC Type 96Pin crimping flat cable supports parallel digital signal transmission, which is important for these systems. Ribbon cables used with IDC connectors help send many signals at once, making the system more efficient.

Key points for automation and control systems include:

IDC connectors create gas-tight connections without stripping insulation.

Only manufacturer-specified cables and tools should be used to ensure proper connection.

Crimping must keep the conductor in the correct position and avoid insulation in the crimp area.

IDC connectors follow strict standards, which ensures compatibility and reliability.

These qualities help automation systems run smoothly and reduce downtime. The connector’s high isolation resistance (≥ 10^5 MΩ) and voltage strength (940 V AC) protect sensitive electronics from electrical faults.

Reliability and Performance

Environmental Resistance

Industrial environments often expose connectors to harsh conditions. The DIN41612 Connector IDC Type 96Pin crimping flat cable shows strong resistance to many environmental factors. Engineers design these connectors to work in places with dust, moisture, vibration, and temperature changes. The materials used in the connector, such as high-grade plastics and plated contacts, help prevent corrosion and wear.

Note: Environmental resistance means the connector can keep working even when conditions are tough.

Key features that support environmental resistance include:

Wide operating temperature range, often from -55°C to +125°C.

High resistance to vibration and shock, which protects connections during machine operation.

Flame-retardant materials that meet UL 94-VO standards.

Sealed contacts that block dust and moisture.

The table below highlights what environmental factors the connector can handle:

| Environmental Factor | Resistance Level |

|---|---|

| Temperature | -55°C to +125°C |

| Vibration | High |

| Moisture | Sealed contacts |

| Flammability | UL 94-VO rated |

| Corrosion | Plated contacts |

These features help the connector last longer and reduce the risk of failure in industrial equipment.

Signal Integrity

Signal integrity means the connector can send signals without loss or interference. The DIN41612 Connector IDC Type 96Pin crimping flat cable supports high signal quality. Engineers use this connector in systems that need fast and accurate data transfer.

Several design choices help maintain signal integrity:

Short and uniform signal paths reduce electrical noise.

Gold or tin plating on contacts lowers resistance and prevents oxidation.

The triple-row layout keeps signals organized and separated.

Tip: Good signal integrity helps machines avoid errors and downtime.

The connector’s design supports both analog and digital signals. It also works well with shielded cables, which block outside electrical noise. These features make the connector a reliable choice for critical industrial systems.

Installation and Standards

Assembly Best Practices

Proper assembly ensures that the DIN41612 Connector IDC Type 96Pin crimping flat cable works reliably in industrial equipment. Technicians use special IDC tools or crimping machines to attach wires to the connector. Each method requires careful attention to detail.

Technicians must keep contacts clean and free from contamination. Clean contacts help prevent signal loss and electrical faults.

Proper registration of IDC cables is important. The wires must align with the connector slots before pressing them in.

Electrical tests check the quality of each connection. Continuity testing with a multimeter helps find open circuits or short circuits.

Resistance measurements use milliohm meters. Good connections show resistance values of about 2.5 ohms or less.

High voltage tests, called hipot tests, apply up to 10,000 volts to check insulation strength.

Pull tests use machines to check the strength of crimped joints. A strong crimp can hold up to 50 pounds before breaking.

Tip: Automated testing systems, like RTS or TS1300, combine electrical, mechanical, and environmental checks. These systems give real-time feedback and help maintain high assembly standards.

Quality and Compliance

Quality control and compliance with standards keep industrial systems safe and reliable. The DIN41612 Connector IDC Type 96Pin crimping flat cable follows strict rules set by DIN and IEC standards. These standards make sure connectors from different brands work together.

Regular maintenance includes checking for loose wires, damaged insulation, or worn contacts.

Troubleshooting starts with visual inspection, then moves to electrical testing.

Adhering to DIN standards ensures that connectors fit and function in many types of equipment.

Quality checks use automated systems to track test results and spot problems early.

| Quality Check | Purpose | Typical Method |

|---|---|---|

| Visual Inspection | Find physical defects | Magnifying glass, camera |

| Continuity Testing | Check for open/short circuits | Multimeter, automated tester |

| Resistance Testing | Measure connection quality | Milliohm meter |

| Pull Test | Assess mechanical strength | Motorized pull tester |

| Hipot Test | Verify insulation integrity | High voltage tester |

Note: Following these best practices and standards helps keep equipment running smoothly and reduces downtime.

The DIN41612 Connector IDC Type 96Pin crimping flat cable gives industrial equipment strong, reliable connections. This connector supports high-density signals and helps machines work without errors. Choosing the right termination method, like IDC or crimping, improves performance and reduces downtime. Engineers should follow standards and check quality to keep systems safe and efficient.

Using standard connectors helps different machines work together and makes repairs easier.

FAQ

What is a DIN41612 Connector IDC Type 96Pin crimping flat cable?

A DIN41612 Connector IDC Type 96Pin crimping flat cable is a standardized connector with 96 pins. It connects multiple electronic boards in industrial equipment. This connector supports high-density signal transmission and ensures reliable performance in harsh environments.

What makes IDC termination different from crimping?

IDC termination presses wires into slots without stripping insulation. Crimping requires stripping the wire and using a tool to attach the connector. IDC works faster and suits mass production. Crimping provides extra mechanical strength for special applications.

What applications use the DIN41612 Connector IDC Type 96Pin crimping flat cable?

Engineers use this connector in rack-based systems, automation controls, and test equipment. It supports board-to-board and backplane connections. The connector’s design fits industrial, telecom, and military devices.

What standards does the DIN41612 Connector IDC Type 96Pin crimping flat cable meet?

This connector meets IEC 60603-2 and EN 60603-2 standards. These standards ensure compatibility, safety, and reliability. Products from different manufacturers can work together when they follow these guidelines.

What are the main benefits of using this connector in industrial equipment?

The connector offers high-density connections, strong environmental resistance, and reliable signal integrity. Its standardized design allows easy repairs and upgrades. Engineers choose it to reduce downtime and improve system performance.