What Makes Charging Pogo Pins Perfect for High Current Needs

Release time:

2025-09-08

What Makes Charging Pogo Pins Perfect for High Current Needs

Charging Pogo Pins give you stable and efficient power transfer for high current needs. You find them in many industries and devices that demand reliable charging:

Battery charging stations for smartphones and drones use pogo pins for thousands of cycles.

Electric vehicles and automotive systems rely on them for battery testing and charging, even in tough conditions.

Medical devices need safe and steady power delivery, making pogo pins essential for portable monitors.

Consumer electronics like wearables use pogo pins for sleek, cable-free charging.

Key Takeaways

Charging Pogo Pins provide stable power transfer, making them ideal for high current applications like electric vehicles and medical devices.

Their spring-loaded design ensures reliable connections, even under shock and vibration, allowing for many uses without wear.

Low contact resistance in pogo pins reduces power loss and heat generation, enhancing safety and efficiency in devices.

Durable materials and smart designs allow pogo pins to last up to 100,000 cycles, making them a cost-effective choice over time.

Pogo pins operate effectively in extreme temperatures, ensuring reliable performance in various environments.

Charging Pogo Pins

Structure

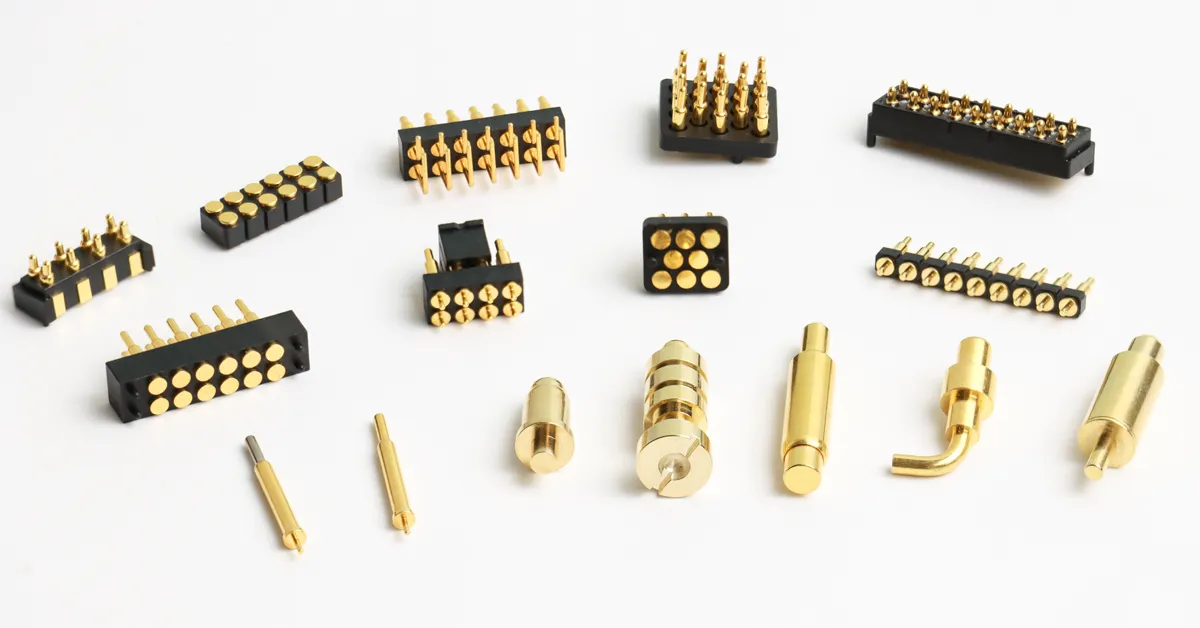

You see Charging Pogo Pins in many modern devices. These connectors have three main parts: the needle shaft, the spring, and the needle tube. Each part plays a special role in making sure you get a strong and stable connection.

The barrel holds everything together and gives the pin its shape.

The plunger moves forward when you press the pin, creating contact.

The internal coil spring keeps the connection tight and reliable.

Manufacturers use brass or copper alloys for these parts. They often add nickel or gold plating to improve electrical conductivity and reduce contact resistance. This design lets you group many pins close together, which helps transfer high current in compact spaces.

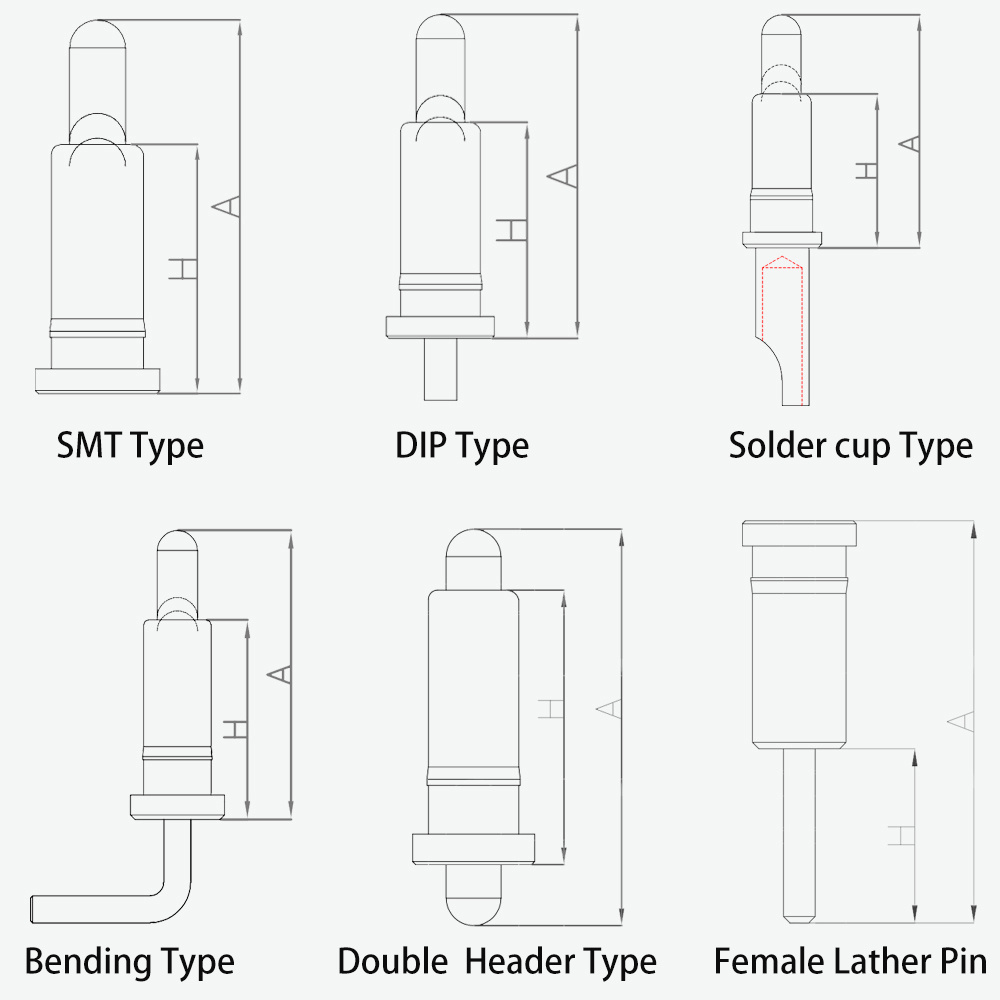

Charging Pogo Pins come in different shapes and sizes. You find flat bottom, plug plate, bending, and double needle shaft types. For example, the DGHECON 4.0mm 3pin connector uses a precise spring inside the needle tube. This structure gives you high current resistance and durability. The spring mechanism keeps the needle shaft and tube in good contact, so you get less signal loss and more stable performance.

Conventional pogo pins, made of a needle shaft, spring, and needle tube, provide good contact reliability and stability. They are designed to maintain performance even under strong external impacts, ensuring effective current transfer.

How They Work

Charging Pogo Pins use a spring-loaded mechanism to create a solid electrical connection. When you press the pin against a surface, the spring compresses. This action pushes the plunger forward, making contact and allowing current to flow. You can adjust the spring’s strength to make sure the connection stays reliable, even when you need to transfer high current.

The spring absorbs shock and vibration, so the connection stays stable.

The design allows for temporary connections, which means you can use the pins many times without wearing them out.

Charging Pogo Pins adjust to different surfaces, so you do not need perfect alignment for a good connection.

You see these connectors in many high current applications. The table below shows some common scenarios:

| Application Scenario | Benefits of Pogo Pins |

|---|---|

| GPS Trackers | Reliable performance and secure connections in compact designs |

| LED Lighting Systems | High current handling and adaptability to environmental stress |

| RFID Readers | Efficient current transfer and modular design capabilities |

Charging Pogo Pins give you a dependable solution for devices that need strong, repeatable, and safe electrical connections.

Key Features

Power Transfer

You need stable power transfer when you work with high current devices. Charging Pogo Pins give you this stability because of their strong design and advanced engineering. These connectors handle strong current changes and keep your devices running smoothly. You can trust them in extreme environments, and they help prevent overheating failures.

Strong current fluctuation tolerance

High reliability

Adaptability to extreme environments

Prevention of overheating failure

Charging Pogo Pins go through tough tests to prove their power transfer abilities. For example, they can run a continuous power-on test for 10,000 cycles at 3A or 4A without any damage or abnormal heating. Their resistance stays below 10 milliohms, and the voltage drop remains under 20 millivolts during dynamic testing. Even during a thermal runaway limit test, the temperature rise stays below 20°C. This means you get safe and efficient power transfer every time.

Contact Resistance

Low contact resistance is key for high current performance. Charging Pogo Pins use special designs and materials to keep resistance low. This helps reduce power loss and keeps your devices cool.

| Component | Description |

|---|---|

| Concentrated Resistance | Resistance due to the contraction of current lines at the contact surface. |

| Film Layer Resistance | Resistance caused by surface films and contaminants, affecting the interface. |

| Conductor Resistance | Resistance from the conductive properties of the metal and the lead wire, including temperature effects. |

You want low resistance in all these areas. Charging Pogo Pins keep resistance stable, even after thousands of cycles. This means you get reliable connections and less heat buildup.

Materials

The choice of materials makes a big difference in how well Charging Pogo Pins work. Manufacturers use high-quality metals and coatings to boost both durability and conductivity.

| Material | Advantages |

|---|---|

| Beryllium Copper (BeCu) | High fatigue resistance; maintains force even after 100,000 cycles. |

| Inconel 718 | Heat-resistant (up to 650°C); used in aerospace or high-temperature systems. |

| PTFE (Teflon) | Dielectric strength = 60 kV/mm; operates up to 260°C; chemical-resistant. |

| Ceramic (Alumina) | Dielectric strength = 15 kV/mm; operates up to 1,600°C; excellent heat dissipation. |

| Liquid Crystal Polymer | Dielectric strength = 25 kV/mm; operates up to 240°C; lightweight and moldable. |

| Stainless Steel 316 | Corrosion-resistant; operates up to 480°C; ideal for outdoor applications. |

Gold plating on contacts gives you excellent conductivity and corrosion resistance.

Beryllium copper springs and gold-plated contacts help your connector last longer and resist wear.

Brass is more affordable but has lower conductivity and can oxidize in humid places.

You get a connector that works well in many environments and lasts through many cycles. For example, the DGHECON 4.0mm 3pin connector uses brass and PA46, giving you a mechanical life of up to 100,000 cycles and a wide temperature range.

Heat Management

High current can cause connectors to heat up quickly. Charging Pogo Pins use smart designs and materials to manage this heat and keep your devices safe.

| Feature | Description |

|---|---|

| Main Heat Source | Located in the contact area between the needle body and the spring, generating significant Joule heating. |

| Temperature Rise | Can exceed 45°C under continuous current above 10A. |

| Thermal Resistance Structure | Includes contact thermal resistance, axial thermal conductivity impedance, and environmental convection. |

| Thermal Resistance Value | Approximately 10-20°C/W, depending on structure and material. |

| Material Used | High thermal conductivity copper alloy with over 300 W/m·K. |

| Temperature Rise Control Design | Multi-point gold-plated contact design to reduce local contact thermal resistance. |

| Experimental Result | A 1.5mm diameter Pogo Pin at 20A showed a temperature rise of about 30°C, 17% lower than market average. |

You see that the main heat comes from the contact area between the needle and the spring. Charging Pogo Pins use copper alloys with high thermal conductivity to move heat away fast. Multi-point gold-plated contacts lower the local thermal resistance, so the connector stays cooler. In tests, a 1.5mm diameter pin at 20A had a temperature rise of only 30°C, which is much lower than most other connectors.

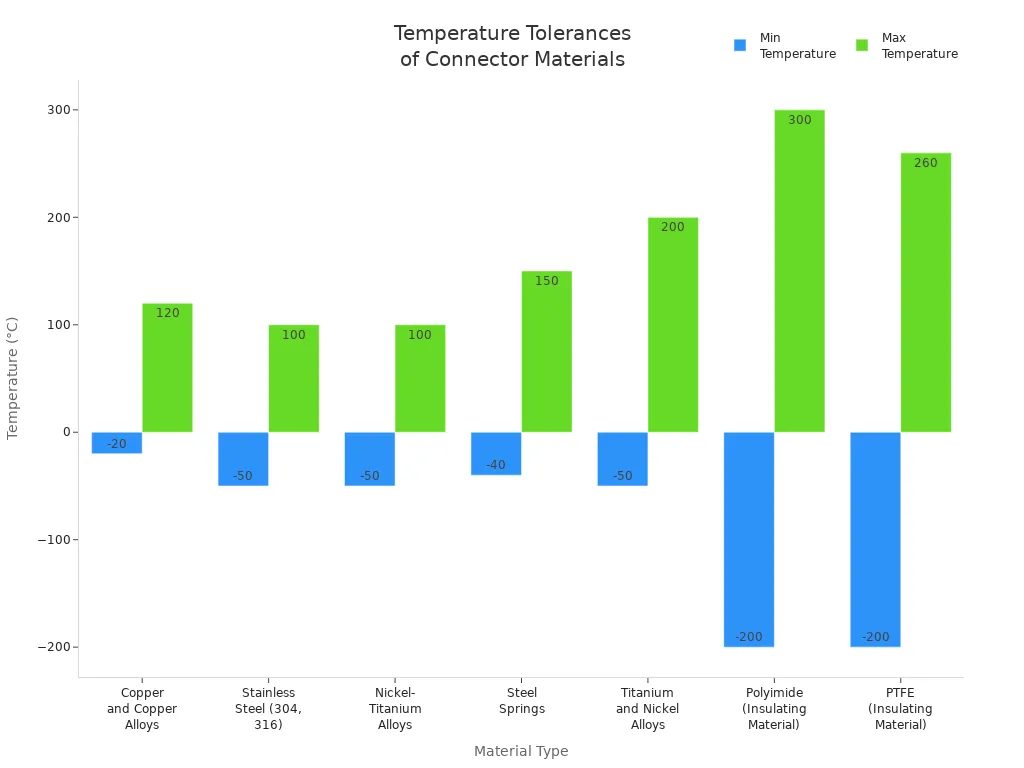

You also need to know the temperature ranges these connectors can handle. Here is a chart that shows the temperature tolerance of different materials:

Charging Pogo Pins can work in a wide range of temperatures, from -40°C to 105°C or even higher, depending on the materials used. This makes them perfect for many high current applications, from outdoor equipment to industrial machines.

Comparison

Traditional Connectors

You may wonder how charging solutions differ when you compare traditional connectors to modern options. Traditional connectors often use simple metal contacts and basic designs. These connectors can struggle with high current loads and may not last as long in demanding environments.

Pogo pins use thicker materials and high-grade metals. This helps them handle more power without overheating or breaking down.

You get better signal integrity with pogo pins because their design reduces resistance and keeps connections stable.

Pogo pins work well for fast charging and high-power devices. Traditional connectors may fail to deliver enough current, which can cause reliability problems.

High current pogo connectors are essential for electric vehicle charging stations. Traditional connectors may not meet these power requirements.

Tip: If you need a connector for high current applications, choose one built with robust materials and advanced engineering.

Here is a table that shows common failure mechanisms in traditional connectors:

| Failure Mechanism | Description |

|---|---|

| Silver Migration | Can lead to increased resistance and eventual failure of the connector. |

| Tin Whiskers | Growth of conductive filaments that can cause short circuits. |

| Corrosion | Deterioration of connector materials, affecting conductivity and reliability. |

| Arc Formation | Occurs under high current, leading to damage and failure of the connector. |

| Creep Failure | Material deformation over time under mechanical stress, impacting connection integrity. |

| Wear | Physical degradation of contact surfaces, leading to poor electrical performance. |

| Frictional Polymerization | Can create unwanted resistance and heat, affecting performance in high current applications. |

Traditional connectors often fail to transmit the intended current. Environmental conditions and material properties can also affect their reliability.

Other Charging Methods

You might see magnetic and USB charging methods in many devices. These methods work well for low to moderate current needs, but they have limits when you need high power.

Charging Pogo Pins create a secure electrical connection with their spring-loaded design. This feature keeps the link strong and helps transfer power efficiently. USB cables can wear out quickly and need frequent replacements. Pogo pins keep working well even after many uses, so you get a more dependable solution.

Magnetic pogo pins cost more because of their advanced features.

The higher price of pogo pins is justified by their compact size, durability, and performance in critical applications.

Traditional connectors are cheaper because they are widely used and produced in large quantities.

Pogo pins cost more to make, but you may save money over time because they last longer and fail less often.

Note: If you need a charging solution for high current and long-term reliability, pogo pins offer clear advantages over other methods.

Practical Benefits

Durability

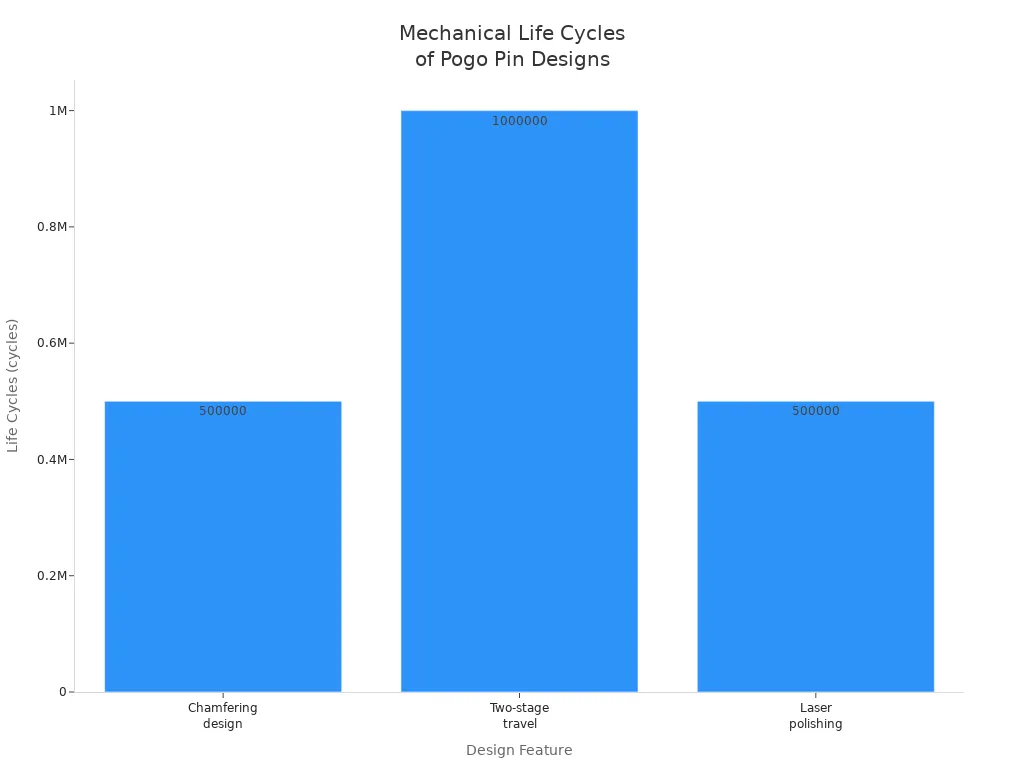

You want your connectors to last through many charging cycles. Charging pogo pins give you impressive durability because of their smart design and strong materials. The DGHECON connector, for example, can handle up to 100,000 cycles and works in temperatures from -40°C to 80°C. Some advanced designs use chamfering, two-stage travel, and laser polishing to push the life cycle even higher.

| Design Feature | Life Cycle Impact |

|---|---|

| Chamfering design | Increases life cycle by 30%, up to 500,000 cycles |

| Two-stage travel | Doubles life cycle at standard 2.5mm travel |

| Laser polishing | Over 500,000 cycles, stable contact after 10,000 uses |

You see that gold plating and composite coatings help pogo pins resist wear and oxidation. These features let you use them in tough environments without worrying about quick failure.

Safety

Charging pogo pins keep your devices safe in many ways. You get stable pressure from the spring contact design, which reduces mechanical damage. Gold or palladium plating protects against corrosion, so your connector stays reliable even after many plug cycles. Waterproof housing lets you use pogo pins in humid or wet places.

| Failure Mode | Description | Mitigation Strategy |

|---|---|---|

| Mechanical Wear | Spring wears out after many cycles | Use high-quality materials and smart design |

| Corrosion | Coatings can corrode in harsh environments | Choose proper materials and environmental controls |

| Misalignment | Poor contact from incorrect positioning | Install and align carefully |

| Contamination | Dust or oxide layers block contact | Clean and maintain contact points regularly |

You lower the risk of failure by picking connectors with these safety features.

Maintenance

You save time and money with charging pogo pins. Their simple design means you spend less on materials and upkeep. You can cut maintenance costs by up to 58% over five years. Pogo pins also make connections easy. You press to mate, and the connector adjusts for small misalignments. This convenience helps in places like charging docks and wearable devices.

Pogo pins need less frequent maintenance than traditional connectors.

You get longer lifespan and less downtime.

Cleaning contact points keeps performance strong.

Tip: Choose charging pogo pins for reliable, safe, and easy-to-maintain connections in high current applications.

Charging pogo pins give you stable power transfer, compact design, and long-lasting durability. You can see their advantages in the table below:

| Feature | Description |

|---|---|

| Stable Power Transfer | Maintains a stable electrical connection under vibration or motion. |

| Compact Design | High current capacity (5 to 20+ amps) without bulky connectors or cables. |

| Durability | Withstands repeated connections (up to 100,000+ mating cycles) without losing conductivity. |

| Safe and Efficient | Lower contact resistance reduces heat generation, enhancing safety. |

You find these connectors in smart glasses, audio devices, and wearables. Experts recommend gold-plated, low-resistance materials and strong springs for high current needs. Choose charging pogo pins for reliable, safe, and efficient connections in your next device.

FAQ

What makes charging pogo pins better for high current applications?

You get stable power transfer and low contact resistance with charging pogo pins. Their gold-plated contacts and strong springs help you handle high current safely.

Tip: Choose pogo pins for devices that need reliable, long-lasting connections.

How long do charging pogo pins last?

Most charging pogo pins last up to 100,000 cycles. Some advanced designs last even longer.

Regular cleaning helps extend their life.

High-quality materials resist wear and corrosion.

Can you use charging pogo pins in extreme temperatures?

Yes, you can use charging pogo pins in temperatures from -40°C to 105°C.

| Temperature Range | Application Example |

|---|---|

| -40°C to 105°C | Industrial equipment |

| -20°C to 80°C | Consumer electronics |

Are charging pogo pins safe for sensitive devices?

You get safe connections with charging pogo pins. The spring-loaded design prevents sparks and overheating.

Note: Gold plating also protects against corrosion, keeping your devices safe.

Do charging pogo pins need special maintenance?

You do not need special tools for maintenance.

Wipe the contacts with a clean cloth.

Check for dust or debris.

Replace only if you see visible wear.