IDC Flat Cable Assembly Shielded or Ribbon Cables Which Wins

Release time:

2025-08-26

Ribbon cables are great for old systems and saving money. They work well in industrial automation and cars. Embedded systems also use ribbon cables. Many engineers like how ribbon cables keep wires neat and flat. Ribbon cables last well in places with lots of shaking. This makes them good for custom harnesses and fixing old machines.

IDC Flat Cable Assembly Shielded or Ribbon Cables Which Wins

In places with lots of electromagnetic interference, IDC Flat Cable Assembly Shielded is often the best choice. It is also picked when data must stay safe. Engineers look at many things before they pick a cable type:

- How many conductors are needed for the signals.

- How much space is inside small devices.

- What the environment is like, such as if there is EMI or high heat.

- What the electrical needs are, like keeping signals clear and fast.

- If the cable needs to bend or move a lot.

- How much it costs, and if it fits the budget.

Shielded cables are stronger and send signals more safely. Ribbon cables work well when things are simple and there is not much interference.

Key Takeaways

- Shielded IDC flat cable assemblies stop interference very well. They work best in places with lots of electromagnetic noise. They are good for fast and reliable data. Ribbon cables bend easily and cost less. They work well for simple or old systems. These systems do not have much interference. Speed is not very important there. Shielded cables fit into small spaces. They last longer than ribbon cables. They also resist heat, chemicals, and damage better. Picking the right cable depends on where you use it. It also depends on data needs, how much it bends, cost, and how long it should last. HECON makes shielded cables you can customise. They deliver them quickly and have safety certificates. This means they are good quality and work well for hard jobs.

Quick Comparison

Key Differences

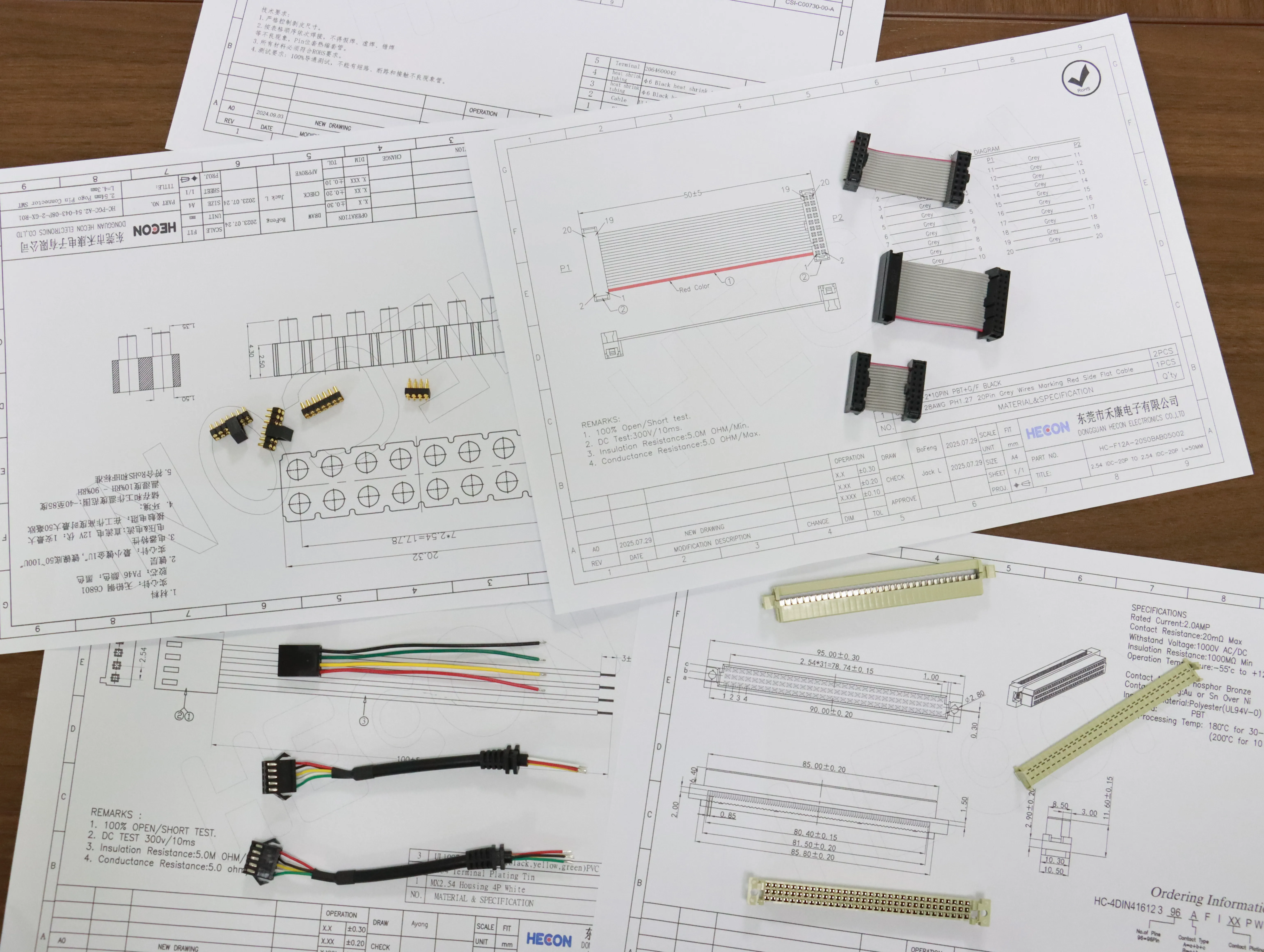

IDC flat cable assemblies and ribbon cables look alike in some ways. But they also have clear differences. IDC flat cable assemblies use parallel conductors with a set pitch. This helps with mass termination using IDC connectors. Shielding is important in many IDC flat cable assemblies. It helps lower electromagnetic interference (EMI). Ribbon cables are often unshielded. They bend and move more easily. This makes them good for places where cables need to twist or bend a lot.

Note: Both cable types can use IDC connectors. Their steady shape helps keep electrical performance stable. This includes predictable capacitance and impedance.

Main Advantages

IDC Flat Cable Assembly Shielded Cables

- Give strong protection against EMI. This makes them great for places with lots of interference.

- Support fast data speeds. Some can handle up to 20 Gbps.

- Keep signals reliable because of controlled impedance and shielding.

- Fit well in small spaces, like inside computers or tiny devices.

- Can be customised for connector type and cable length.

Ribbon Cables

- Are very flexible. This helps when cables must bend or twist.

- Make assembly quick and routing easy in tight spaces.

- Are cheaper for simple or older uses.

- Have steady electrical features because of their parallel conductor layout.

Both cable types can send data quickly, depending on how they are made and used. Shielded IDC flat cable assemblies work best where signal safety and reliability matter most. Ribbon cables are simple and flexible for everyday electronic connections.

Performance

Shielding & Signal

IDC Flat Cable Assembly Shielded is very good at blocking interference. HECON’s cables use a black heat shrink tube for extra safety. The UL20267 wire helps the cable work well. Gold-plated terminals make the connectors last longer and work better. These things help keep signals clear and strong, even with lots of interference. The flat shape lets heat escape, so it can carry more current without losing signal. Most ribbon cables do not have shielding. This makes them easier to get signal problems, especially in tricky systems.

EMI/RFI Protection

Shielding is important for stopping electromagnetic and radio-frequency interference. IDC Flat Cable Assembly Shielded uses foil, braided, or spiral shielding. Each type gives different coverage and flexibility. The table below shows how these types compare to ribbon cables without shielding:

IDC Flat Cable Assembly Shielded gives strong protection from EMI and RFI. This stops outside noise from messing up signals. Ribbon cables without shielding cannot protect as well. So, they can get more interference in tough places.

Data Quality

Good data quality means the cable keeps signals clear and blocks outside noise. IDC Flat Cable Assembly Shielded is great at this. Shielding, good insulation, and gold-plated contacts help send data well. These cables work in hot places, up to 260°C. The flat design with separate wires helps with heat and current. Ribbon cables may have trouble with data if it gets hot or noisy. They are better for simple jobs where data is not as important.

Tip: If you need steady data and protection from noise, IDC Flat Cable Assembly Shielded is a good choice.

Applications

Environments

IDC Flat Cable Assembly Shielded works best in tough places. These cables do well where there is lots of electromagnetic interference. Factories and telecom systems are good examples. Engineers pick them for spots near power cables or motors. These places often have lots of electromagnetic noise. The cables also work outside and in automation systems. Here, strength and keeping signals safe are very important.

- Manufacturing equipment

- Telecommunications systems

- Instrumentation for control and measurement

- Industrial automation

- Outdoor installations exposed to harsh weather

Strong jackets like TPE or PE help these cables last longer. They stop damage from rubbing, chemicals, and high heat. This makes the cables good for hard jobs.

Use Cases

Engineers use IDC Flat Cable Assembly Shielded in new electronic devices. These devices need small and strong wiring. HECON’s cables fit LED displays, printers, and telecom gear. They also work in small electronics where space is tight. You can choose different tubing, connectors, and cable shapes. This helps the cables fit special spaces and needs.

- LED displays and lighting systems

- Printers and office equipment

- Telecommunications and networking devices

- Compact industrial controllers

- Custom electronic assemblies

Old ribbon cables are still used for easy or old jobs. These include older computer parts and simple machines. They are fine when electromagnetic interference is not a problem.

Flexibility

Shielded IDC flat ribbon cables have soft cores and bendy insulation. This lets the cables twist and bend without breaking. They fit well in small spaces because the wires are neat and small. These cables stand up to wear, heat, oil, and cold. They are good for moving a lot and tough places.

Note: IDC Flat Cable Assembly Shielded is flexible and strong. This makes it great for new, small, and portable electronic devices.

Cost & Practicality

Price

Price is important when picking a cable. Ribbon cables cost less at first. This makes them good for simple or old systems. IDC Flat Cable Assembly Shielded costs more but gives better value in hard places. HECON lets you order as few as 50 cables. This helps small and big projects save money. You get samples in 3-7 days. Big orders take about 15 days. You can pay with T/T, PayPal, or Alibaba Pay.

Note: HECON answers support questions in 8 hours. This helps customers who need quick help.

Installation

Installation should be fast and easy. IDC Flat Cable Assembly Shielded comes in many lengths and connector types. This helps it fit in small or tricky spaces. The flat shape keeps cables tidy and neat. This stops mess inside devices. HECON packs cables in PE bags or special boxes. This keeps them safe when shipped or stored. Labels and good connectors help stop mistakes. This saves time and lowers the chance of errors.

Durability

Durability is key in tough or moving places. The table below shows how cables do under stress:

IDC Flat Cable Assembly Shielded lasts a long time and is very tough. It stands up to shaking, bumps, and strong chemicals. This makes it good for factories and outside use.

Certifications are also important when choosing cables. The table below shows common certifications and what they mean:

HECON’s cables have UL, CE, and RoHS certificates. They also have a 24-month quality guarantee. This helps buyers feel safe about the cables’ safety and reliability.

Ribbon Cables: Pros & Cons

Pros

Ribbon cables are still used in many old and built-in electronic systems. Their design gives some useful benefits:

- Simple and Fast Termination: IDC technology lets engineers finish ribbon cables quickly. You do not need to strip wires, so it saves time.

- Space Efficiency: Ribbon cables are flat and small. This helps keep wires tidy and neat. They fit well in devices with little space.

- Parallel Signal Transmission: Ribbon cables can carry many signals at once. This is good for old computers, printers, and built-in systems. These jobs do not need perfect data speed.

- Cost-Effectiveness: For easy jobs, ribbon cables are cheap. The way they are made keeps the price low.

- Ease of Use in Legacy Systems: Many old devices use ribbon cables. Engineers can fix or upgrade these without worrying about fitting.

Note: Ribbon cables work well for many old electronic jobs. They are best where there is not much electromagnetic interference.

Cons

Even with their good points, ribbon cables have some problems in new and hard jobs:

- Limited Flexibility: Ribbon cables mostly bend one way. If you bend them another way, they can break or lose signals.

- Challenging Installation: Ribbon cables are stiff and wide. This makes it hard to fit them in cabinets or racks. Putting them inside can take more time and care.

- Susceptibility to Interference: The flat wires can pick up noise from other signals. This can make signals weak in noisy places.

- Mechanical Reliability Issues: If you bend them a lot, the wires can snap. Heat can make the cover soft, so it wears out faster.

- Environmental Limitations: Ribbon cables do not do well in tough places. They do not stand up to chemicals, heat, or strong hits as well as shielded cables.

Tip: For fast data, tough places, or lots of interference, engineers should pick shielded cable assemblies for better results.

Decision Guide

How to Choose

Picking the right cable needs careful thought. Engineers look at where the cable will be used. They check if there is a lot of interference. They think about what the device needs. The budget matters too. How long the system should last is also important. The table below shows the main things to think about:

Tip: Always pick a cable that suits the place and how important signal quality is.

When to Use Shielded

Engineers pick IDC Flat Cable Assembly Shielded for tough jobs. These cables block strong electromagnetic interference. They keep data safe and signals clear. They work well near motors and power supplies. Wireless devices also need shielded cables. These cables are good for fast data and small electronics. Their strong build makes them last in hard places and outside.

- Use in places with lots of EMI or RFI.

- Pick for jobs needing steady, fast data.

- Choose for small devices with little space.

- Use when you need cables that last a long time.

Note: Shielded cables often have UL, CE, and RoHS certificates. This helps you trust their safety and quality.

When to Use Ribbon

Ribbon cables are great for old systems and saving money. They work well in industrial automation and cars. Embedded systems also use ribbon cables. Many engineers like how ribbon cables keep wires neat and flat. Ribbon cables last well in places with lots of shaking. This makes them good for custom harnesses and fixing old machines.

- Keep using ribbon cables in old systems.

- Use in industrial automation and car subsystems.

- Pick for neat, packed connections.

- Choose when you need to save money, especially for big orders.

- Use in custom harnesses needing even wire spacing.

Tip: Ribbon cables are cheap and reliable. They are best for projects with small budgets or old designs.

Engineers should pick shielded IDC flat cable assemblies for places with lots of interference. These cables are also good when you need them to last long and not need much fixing. Ribbon cables work well for old systems and when you want to save money. Certifications like UL and RoHS help make sure the cables are safe and will last a long time. Good help after you buy the cables also makes them more reliable.

Always choose the right cable for where and how you will use it. Think about if the cable can handle heat, if it bends easily, and if it is simple to put in. This helps you get the best results.

FAQ

What is the main benefit of using shielded IDC flat cable assemblies?

Shielded IDC flat cable assemblies stop interference from affecting signals. They help keep data safe and easy to read in busy places. Engineers pick them for important and sensitive jobs.

Can ribbon cables handle high-speed data transmission?

Ribbon cables can send data at medium speeds. They are best for simple or older systems. For very fast or important data, shielded IDC flat cable assemblies work better.

Are HECON IDC flat cable assemblies customisable?

Yes, HECON lets you choose the length, connector, and shielding. Customers can ask for special features for their projects. This makes them useful for many types of work.

Do these cables meet international safety standards?

HECON cables have UL, CE, and RoHS certificates. These show the cables follow strict safety and environment rules. Buyers can trust they are safe and good quality.

How quickly can HECON deliver custom cable orders?

HECON sends samples in 3 to 7 working days. Big orders are ready in about 15 working days. Fast delivery helps projects finish on time.