SMT Pogo Pin Connectors Explained with a Focus on Durability

Release time:

2025-08-20

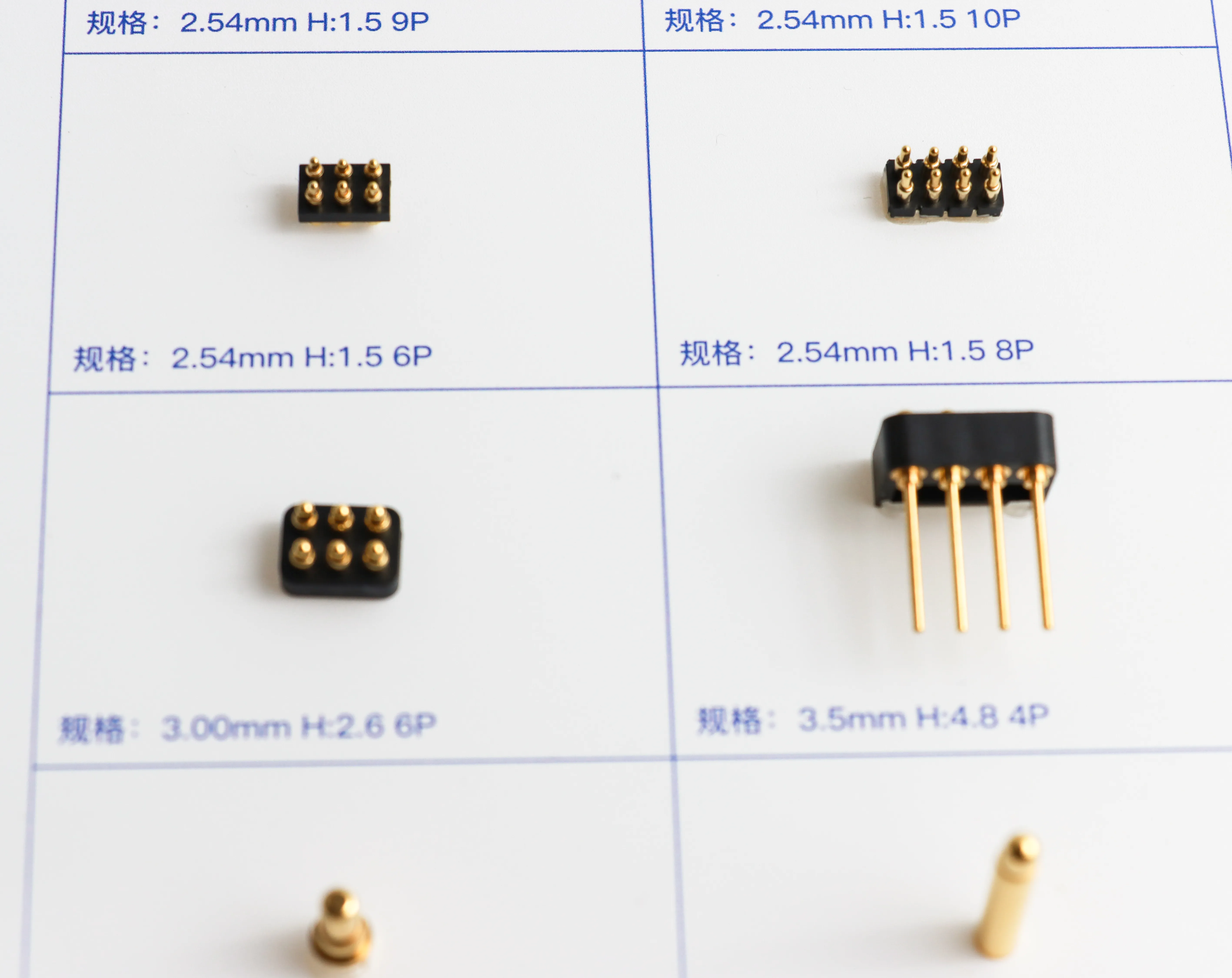

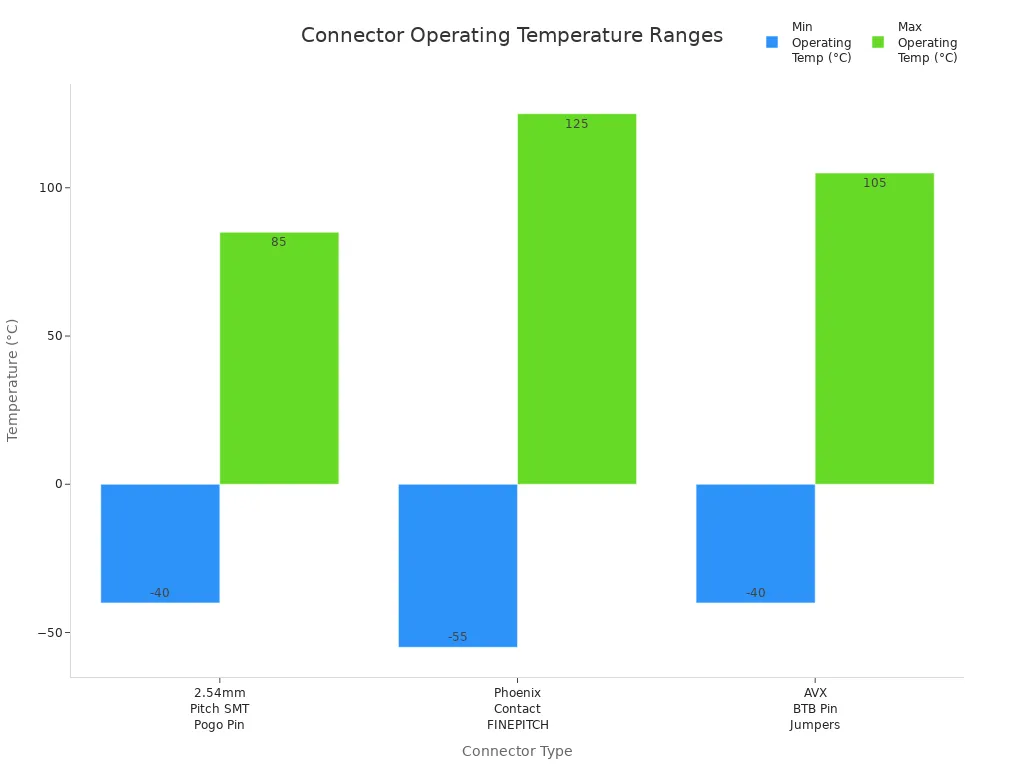

The 2.54mm Pitch SMT Pogo Pin Connector works from -40°C to +85°C. This is good for most outdoor and factory jobs. Some special types can take heat up to 250°C. The table below shows how this connector matches up with

SMT Pogo Pin Connectors Explained with a Focus on Durability

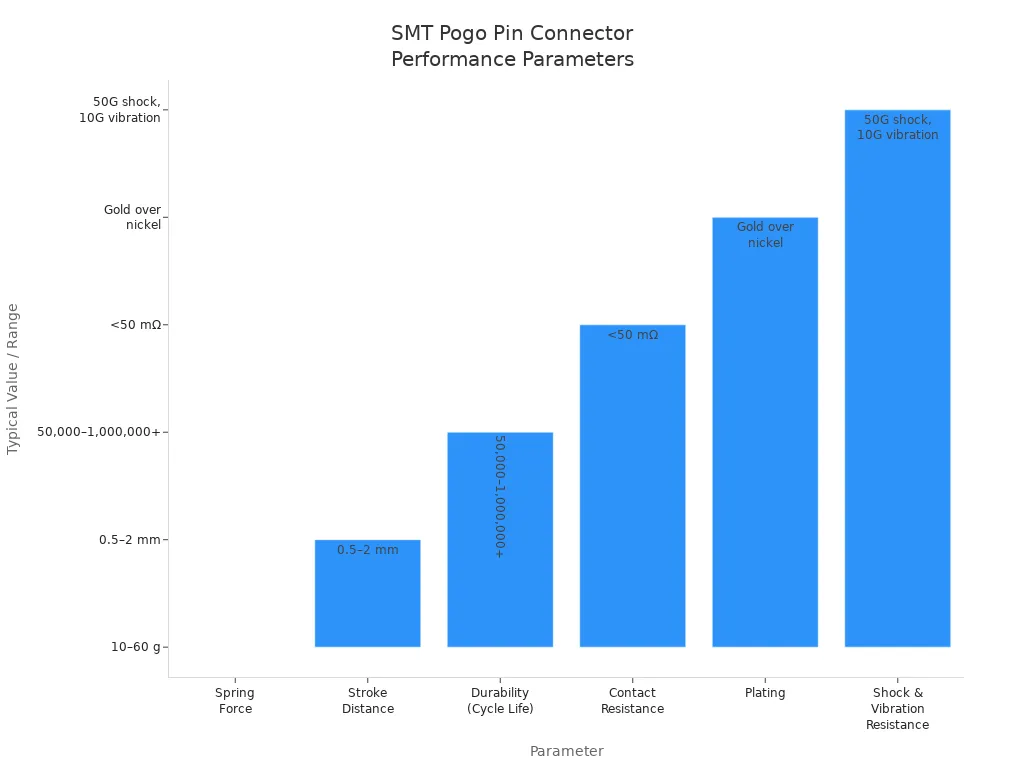

Durability is the most important thing about SMT Pogo Pin Connectors. Makers use gold-plated brass for plungers. They use beryllium copper for springs. They also use special engineering to make these connectors. Gold plating helps electricity flow better. It also keeps the connectors safe from rust. This careful building makes sure the connectors work well and last long. Industry numbers say connector failures cause about 40-50% of device problems. This shows how important durability is. Devices need these connectors to work well when things get tough. Strong design and careful assembly are very important.

Key Takeaways

·SMT Pogo Pin Connectors are made with tough materials. They use gold-plated brass and stainless steel springs. These materials help the connectors last a long time. They also make sure connections stay strong.

·The spring inside the connector keeps pressure steady. This helps the connector work well even if it shakes or gets bumped. It can be used many times, up to 100,000 cycles or more.

·Special coatings and strong plastics protect the connectors. They keep out rust, dust, and water. They also help the connectors handle very hot or cold temperatures. This makes them good for hard environments.

·Picking the right connector is important. You need to match the pin count, size, current, and temperature needs. Gold plating and smart design help the connector last longer.

·Cleaning connectors with isopropyl alcohol helps them stay good. Careful installation also helps them last longer. This keeps devices working well.

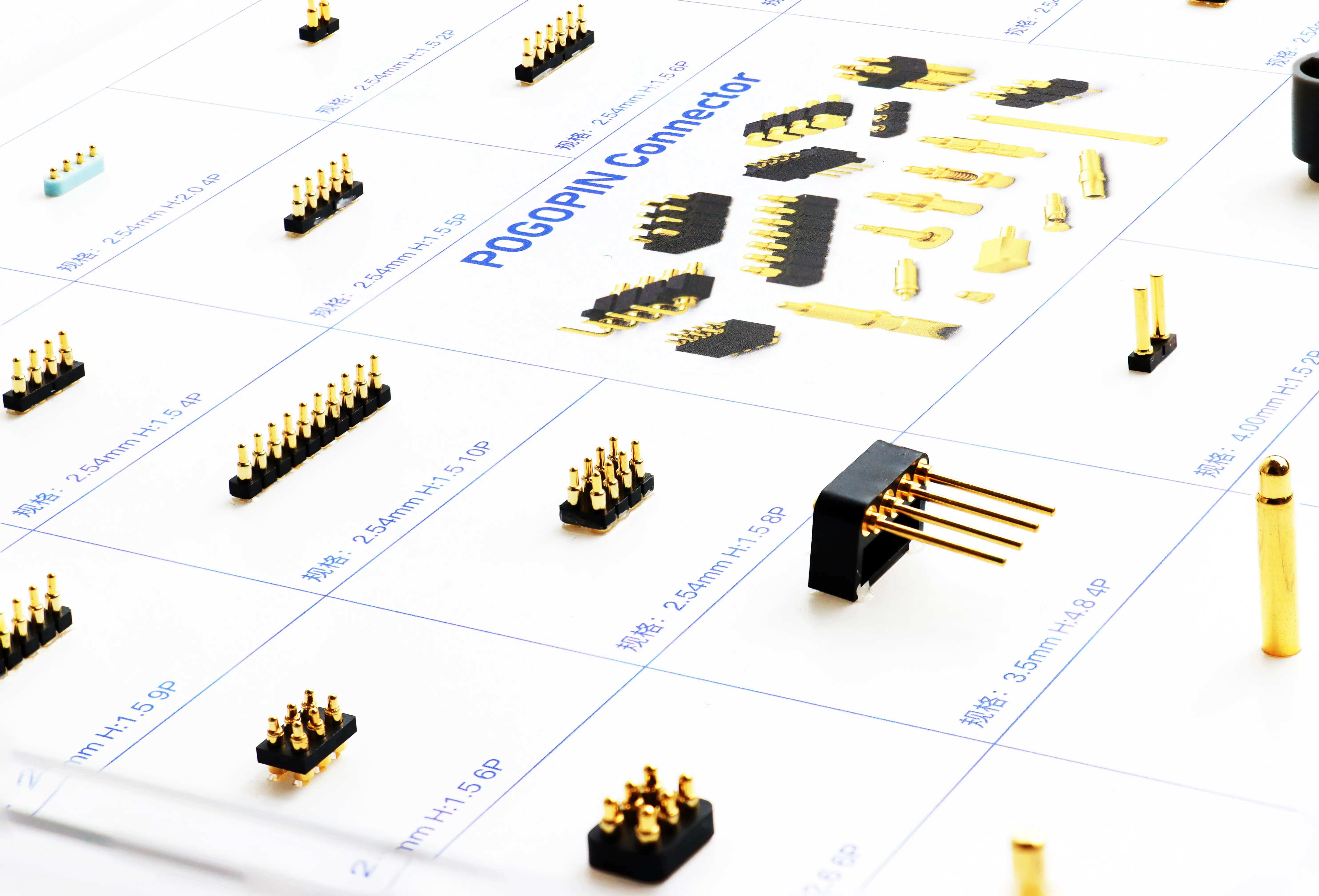

SMT Pogo Pin Connectors Overview

Structure

SMT Pogo Pin Connectors are made with three main parts. The Plunger is the tip that moves and touches the other surface. Makers put gold on the plunger. This helps electricity move and stops rust. The Spring is inside the barrel. It pushes the plunger out. This keeps pressure steady. It also lets the connector fit small changes in height. The Barrel (Body) holds the plunger and spring together. It connects the pogo pin to the board or cable.

All these parts work together for a strong connection. The spring helps the connector stay put if the device shakes. The plunger wipes away dust or dirt. This keeps the contact area clean.

| Component | Material Choices | Contribution to Performance |

|---|---|---|

| Plunger | Brass, copper, beryllium copper, stainless steel; gold plating | Reliable contact, great conductivity, corrosion resistance, durability |

| Spring | Copper alloys, spring steel, beryllium copper, stainless steel | Consistent force, long life, shock and vibration resistance |

| Barrel (Body) | Brass, copper | Mechanical stability, houses other parts |

Function

SMT Pogo Pin Connectors are important in today’s electronics. The spring keeps the plunger pressed on the contact point. This gives steady pressure. The connector works well even if the device shakes or gets hot or cold. It can be used many times without breaking. This makes it last longer than many old connectors.

You can find these connectors in phones, tablets, wearables, and medical tools. They help with charging and sending signals. They also connect different parts inside a device. The spring-loaded design lets the connector fit small mistakes during assembly. This makes it good for tight spaces.

Note: SMT Pogo Pin Connectors are stronger and last longer than many old connectors. Their small size and good performance make them a favorite for engineers who build new electronics.

Design & Materials

Spring Mechanism

The spring is the most important part of a pogo pin connector. It pushes the plunger onto the contact point. This keeps the connection steady. The 2.54mm Pitch SMT Pogo Pin Connector has a special spring in each pin. This spring can move 1.0mm when working and up to 1.4mm at its limit. The type of spring material is very important for how long it lasts and how well it works.

| Material | Properties | Effect on Durability |

|---|---|---|

| Stainless Steel (SUS304) | Good elasticity, corrosion resistance | High durability, keeps shape in harsh environments |

| Music Wire (Carbon Steel) | High elasticity | Less durable, shorter lifespan |

| Beryllium Copper Wire | Long-lasting under high stress, lower elasticity | Great for high-stress, but less elastic |

Most SMT Pogo Pin Connectors use stainless steel springs. These springs do not rust and keep their shape even if it gets hot or cold. This helps the connector last longer and work well in hard places. The spring gives a steady force, about 90g at a 1.0mm stroke. This force keeps the connection strong, even if the device shakes. The spring design lets the connector be used up to 100,000 times without breaking.

| Feature | Description |

|---|---|

| Spring Material | Stainless Steel (SUS) with surface treatment |

| Contact Force | About 90g ±20g at 1.0mm stroke |

| Full Stroke | About 1.4mm |

| Mechanical Life | Up to 100,000 cycles |

| Design Detail | Compression spring keeps plunger engaged |

The spring helps the connector stay connected. It also lets it survive shaking, bumps, and changes in temperature.

Plating & Housing

The materials for plating and housing help the connector last longer. The 2.54mm Pitch SMT Pogo Pin Connector uses a brass needle shaft with gold flash plating. Brass makes the pin strong and helps electricity move well. Gold plating makes the surface smooth and stops rust. This keeps the contact resistance low, often as low as 30mΩ, and helps current flow easily.

·Gold flash plating helps stop rust and lets electricity move better.

·The gold surface helps the connector send signals fast and clear.

·Salt spray tests show the connector can fight rust for 48 hours.

·The brass needle shaft can handle up to 1A of current and 12V.

·The connector can be used up to 100,000 times, so it is good for many uses.

The housing is made from PA6T, a strong white plastic. PA6T can take high heat and does not soak up much water. This keeps the connector strong in hot or wet places. The connector works from -40°C to 105°C, so it fits many different places.

| Aspect | Details |

|---|---|

| Needle Shaft Material | Brass (3604) |

| Plating | Gold flash plating |

| Housing Material | PA6T plastic |

| Operating Temp. | -40°C to 105°C |

| Salt Spray Resistance | 48 hours |

| Mechanical Strength | High, resists wear and tear |

The right materials help SMT Pogo Pin Connectors last longer. They stop rust and keep working even when things get tough

.

Durability & Failure Modes

Wear Resistance

Wear resistance is very important for SMT Pogo Pin Connectors. These connectors are used many times in real life. The 2.54mm Pitch SMT Pogo Pin Connector can be used up to 100,000 times. Some special pogo pins can last over 200,000 times. This is much longer than many other connectors. Some regular connectors stop working after just a few thousand uses.

Many things help these connectors last longer:

·Gold on the contact parts makes less rubbing and stops rust.

·Special springs keep the force the same, even after lots of use.

·Brass and stainless steel do not bend or wear out easily.

Cleaning with isopropyl alcohol and soft swabs gets rid of dirt. This dirt can make the connector wear out faster. Lining up the connector right stops it from bending or breaking. Keeping connectors in dry places also stops rust, even on gold pins.

| Feature | SMT Pogo Pin Connectors | Standard Connectors |

|---|---|---|

| Mechanical Life | 100,000–200,000+ cycles | 5,000–10,000 cycles |

| Contact Material | Gold-plated brass/copper | Tin or nickel plating |

| Wear Resistance | High | Moderate |

| Maintenance Needed | Minimal | Regular |

Good wear resistance keeps the connection working after many uses. This is very important for things like wearables, medical tools, and machines. These devices need connectors that work every time.

Tip: Do not press the pins too hard. Keep connectors clean to help them last longer.

Environmental Protection

Environmental protection helps SMT Pogo Pin Connectors work in tough places. These connectors use gold, rhodium, or palladium-nickel to keep contact good. They work well even in wet or salty air. The springs are made from beryllium copper or stainless steel. These springs keep their shape in hot or cold weather.

The outside is made from strong plastic like PA6T. This plastic does not crack or melt easily. Some connectors have rubber seals or heat shrink tubes. These help keep water out. Many connectors pass IP65 or IP67 tests. This means they block dust and can handle water jets.

Makers test these connectors in salt spray, wet rooms, and hot-cold cycles. The 2.54mm Pitch SMT Pogo Pin Connector can take heat up to 260°C. It works in temperatures from -40°C to 105°C. These tests show the connectors can handle tough building steps and real use.

| Failure Mode | Description and Impact | Design Solution |

|---|---|---|

| Spring Fatigue | Spring gets weak after many uses | Use strong spring materials |

| Over-Compression | Pressing too hard can break the connector | Set limits on how much it can be pressed |

| Plunger Wear | Tip gets smooth and does not touch well | Use strong materials for the tip |

| Corrosion | Rust from water or chemicals | Use coatings that stop rust |

| Thermal Expansion | Parts change shape in hot or cold | Use materials that handle temperature |

Pogo pins are checked by machines to find bad plating. Bad plating can cause rust. Every batch must pass strict tests before shipping. These steps help stop problems from water, dust, or big temperature changes.

Note: SMT Pogo Pin Connectors can handle heat, lots of use, and tough places. This makes them a good choice for hard jobs.

SMT Pogo Pin Connectors Durability

Environmental Stress

SMT Pogo Pin Connectors have to work in tough places. They face things like wet air, dust, and hot or cold weather. Makers put special coatings on the contact points. These coatings stop rust from water and air. Sometimes, there are up to seven layers of coating. This keeps the pins safe, even near salt or chemicals. The design uses closed shapes and dry grease. These things keep out dust and dirt. This stops the plunger from getting stuck.

Engineers test these connectors in hard ways. One test is the salt spray test. It checks if the connector can last 96 hours in salty air. Another test is called the double 85 test. It puts the connector in 85°C heat and 85% wet air for a week. The connector must still work well. The contact resistance should not change much. Some connectors use dome caps to block dust. This helps in things like earphones.

The 2.54mm Pitch SMT Pogo Pin Connector works from -40°C to +85°C. This is good for most outdoor and factory jobs. Some special types can take heat up to 250°C. The table below shows how this connector matches up with others:

| Connector Type | Operating Temperature Range | Special Temperature Capability | Housing Material & Heat Resistance |

|---|---|---|---|

| 2.54mm Pitch SMT Pogo Pin Connector | -40°C to +85°C | Up to 250°C (special design) | PPS engineering plastic, up to 260°C |

| Phoenix Contact FINEPITCH Series | -55°C to +125°C | N/A | High-temp nylon, heat deflection ~260°C |

| AVX Corporation BTB Pin Jumpers | -40°C to +105°C | N/A | N/A |

Note: These tests and materials help SMT Pogo Pin Connectors stay strong in hard places.

Mechanical Stress

Mechanical stress comes from shaking, bumps, and using the connector many times. SMT Pogo Pin Connectors have a spring inside. The spring keeps the connection tight, even if the device moves. The spring also means you do not need to push hard. This helps stop damage. These connectors can be plugged in and out many times.

SMT pogo pins are better than other connectors for shaking and bumps. Their small size and strong case help them stay put during machine work. Some types, like threaded pogo pins, do not come loose even in moving machines.

Makers test these connectors by shaking, bending, and plugging them in a lot. The 2.54mm Pitch SMT Pogo Pin Connector can last up to 100,000 uses. This makes it good for things that open and close often.

Tip: The spring and strong parts help SMT Pogo Pin Connectors last a long time, even when things get rough.

Selection & Maintenance

Choosing the Right Connector

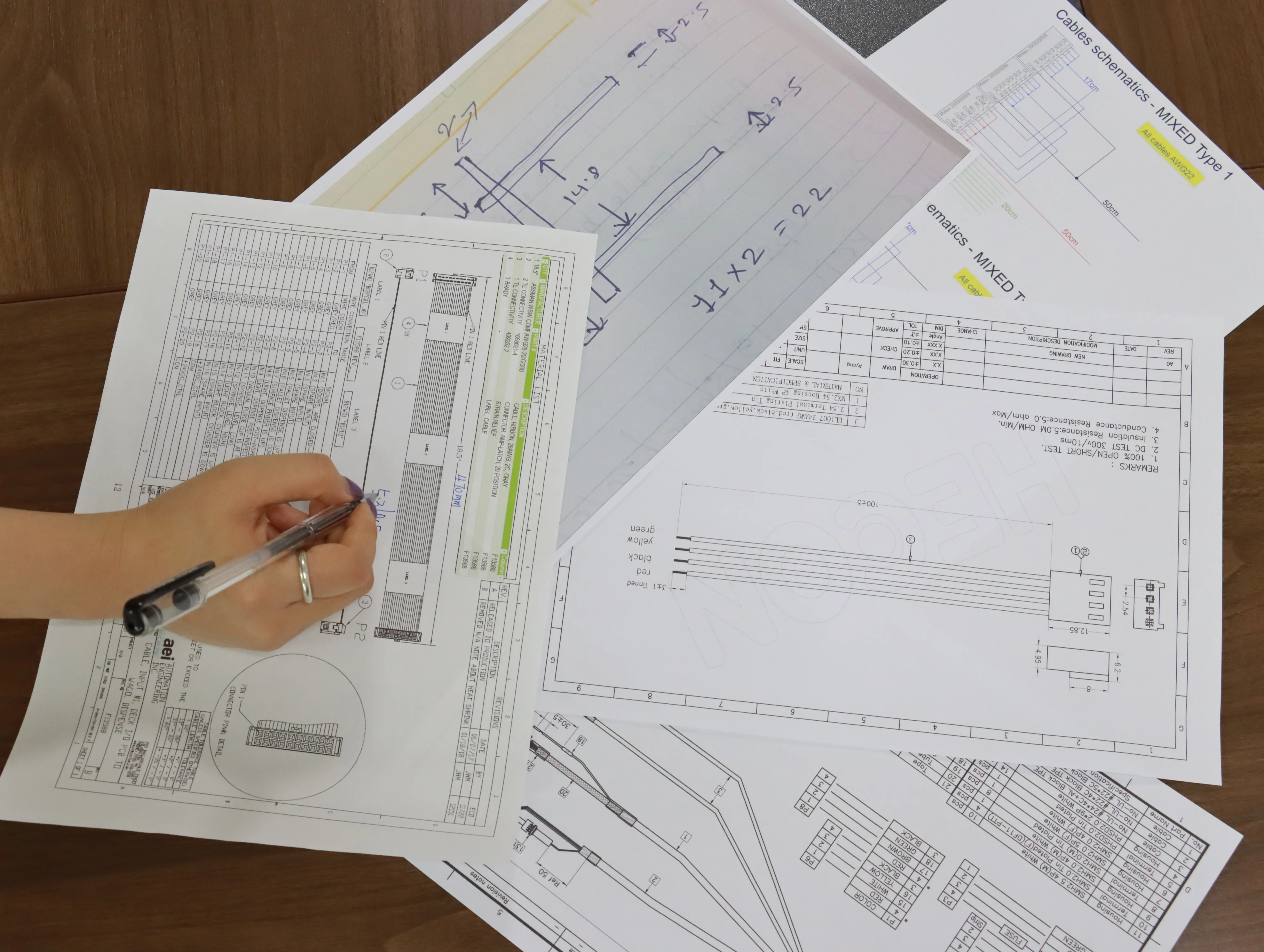

Picking the best pogo pin connector takes careful thought. Engineers first count how many pins the device needs. They check the current rating and stroke length. These must match the device’s power and movement. Pitch size tells how much space the connector uses. Smaller pitch sizes fit more parts in small gadgets. This is good for things like smartphones and wearables. The mounting type must fit the printed circuit board.

The tip shape should match the other surface. Flat contacts need one kind of tip. Recessed contacts need another. Gold plating helps electricity move and stops rust. Good materials like brass, copper, and gold make the connector last longer. Cycle life ratings show how many times you can use the connector. Some pins work over 100,000 times. Temperature and environmental ratings show if it works in hot, cold, or wet places. The connector must also work with other device parts.

Checklist for Selection:

·Number of pins

·Pitch size and mounting type

·Current rating and stroke length

·Tip design for mating surface

·Plating material (gold recommended)

·Cycle life and durability rating

·Operating temperature range

·Contact resistance

·Compatibility with device

Tip: Ask the maker for help if you need a special connector.

Maintenance Tips

Taking care of connectors helps them last longer. Use gold-plated PCB pads to match the pogo pins. This keeps resistance low and the connection strong. Make the pad size and shape fit the plunger tips. Allow for small mistakes in lining up the pins. This helps the pins clean the surface and make better contact. Keep the pads flat so the connection stays good.

Use the connector at the right working height. Pushing too hard or not enough can make it wear out faster. Guide pins or special housing help line up the connector when putting it together. Clean the contact area with isopropyl alcohol and a soft swab. Store connectors in dry places to stop rust.

| Maintenance Step | Benefit |

|---|---|

| Use gold-plated pads | Low resistance, long life |

| Ensure pad flatness | Reliable contact |

| Proper compression | Prevents damage |

| Mechanical guidance | Easy alignment |

| Regular cleaning | Removes dirt, prevents wear |

🛠️ Take care of connectors and install them right. They will work well for many years.

How long a connector lasts depends on many things. The table below lists the main reasons these connectors are strong:

| Durability Factor | Benefit |

|---|---|

| Long Lifespan | Can be used up to 300,000 times |

| Low Contact Resistance | Keeps signals steady for a long time |

| Corrosion Resistance | Many layers of plating stop rust |

| Vibration Tolerance | Stays attached even when things move |

| Sealing Design | Stops water and dust from getting inside |

Picking the right connector and taking care of it helps devices last longer. Checking and cleaning them often stops issues. Tests show strong connectors protect electronics in cars, factories, and medical equipment.

FAQ

Q1: What makes SMT Pogo Pin Connectors durable?

Engineers pick tough materials like brass and PA6T plastic. Gold plating keeps rust away. The spring lets you use the connector many times. All these things help the connector last for years.

Q2: How often should someone clean pogo pin connectors?

People should clean connectors every few months or when dirty. Use isopropyl alcohol and a soft swab to clean them. Clean pins work better and last much longer.

Q3: Can SMT Pogo Pin Connectors handle outdoor use?

Yes, these connectors can be used outside. They block water, dust, and changes in temperature. Gold plating and strong plastic keep them safe. Many types work well in outdoor gadgets.

Q4: What devices use SMT Pogo Pin Connectors?

Lots of devices use these connectors. Some are smartphones, wearables, medical tools, and test gear. Engineers like them because they are small and last a long time.

Q5: How does someone choose the right pogo pin connector?

Tip: Count the pins, check pitch size, current, and temperature range. Pick gold-plated pins for best results. Ask the supplier for help if you are not sure.