How does the environment affect Pogo Pin Connectors

Release time:

2025-07-05

Do you know how various environments affect the Pogo Pin connectors?

The Pogo Pin industry engineer from HECON will be able to answer your questions.

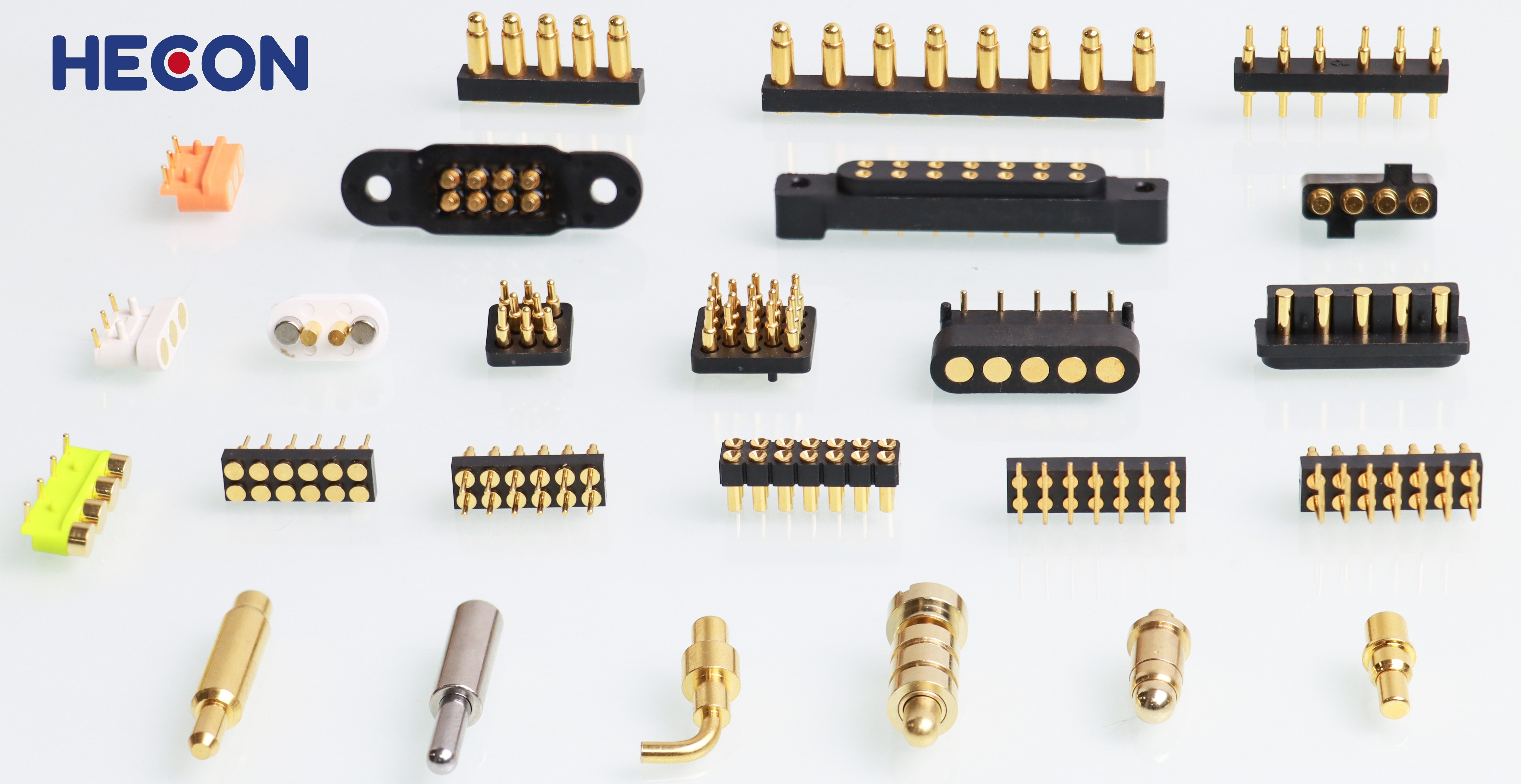

Pogo Pin connectors (Spring-loaded connector) are widely used in smartphones, wearable devices, medical electronics, test fixtures, and even aerospace applications due to their compact size, high reliability, and excellent current transfer capability. However, the realization of its excellent performance is highly dependent on the consideration of the working environment. Different environmental factors can have a significant impact on a connector's physical structure, electrical characteristics and long-term reliability. Today, we'll take an in-depth look at some of the key environmental factors and how they can be addressed:

Temperature: The “hot” challenge of performance.

Extreme range: Typical operating temperatures for today's leading spring-loaded pin connectors range from -65°C to +200°C. This represents the extreme boundary of what materials (e.g., insulating plastics, springs, contact coatings) can withstand.

The core issue: temperature rise. When a connector is in operation, the flow of current through the contacts inevitably generates Joule heat, resulting in a rise in contact temperature. Therefore, the actual operating temperature is equal to the ambient temperature + the temperature rise of the contacts.

Requirements: To ensure safety and longevity, industry specifications often specify the maximum temperature rise allowed for connectors at rated operating currents. Sufficient allowance must be made in the design to prevent overheating from causing material deterioration, contact resistance surge or even failure. High temperatures accelerate oxidation and reduce elasticity; low temperatures may make the material brittle and insufficient contact pressure.

Humidity: the “invisible” threat of insulation and corrosion

Intrusion Risk: Moisture penetration is the enemy of connectors. High humidity can:

Reduce the insulation properties of connectors (especially between pins), increasing the risk of leakage currents or even short circuits.

lead to galvanic corrosion (rust) of metal parts (barrels, pins, springs), destroying electrical conductivity and structural strength.

Reliability verification: For this reason, rigorous constant humidity and heat tests (e.g. temperature 40±2°C, relative humidity 90%-95%), usually of no less than 96 hours duration, have become standard requirements to simulate the long-term effects of harsh humid environments and to screen for non-conformities.

Salt Spray: The “Corrosive Agent” of Coastal and Industrial Environments

Mechanism of Destruction: In environments containing salt and moisture, such as coastal areas, certain industrial scenarios or near automobile chassis, salt spray adheres to connector surfaces. This provides an electrolyte for metal parts and delicate contact finishes (e.g. gold, nickel plating), inducing aggressive galvanic corrosion.

Serious consequences: Salt spray corrosion not only destroys the appearance, but also significantly degrades the connector's physical structural strength and electrical contact properties (e.g., increased contact resistance, signal distortion), and can even lead to a complete loss of functionality. It is important to choose a surface treatment with excellent salt spray resistance.

Vibration and shock: the “stability” test for mechanical connections

Core performance: Resistance to vibration and shock is a key metric for spring-loaded pin connectors, especially in dynamic environments such as aerospace, rail transportation (high-speed rail), automotive electronics, and industrial equipment. Constant vibration or momentary shocks can

Cause microscopic wear at the contact point, damaging the surface plating and increasing contact resistance.

Loosen the connector or break the contact momentarily, causing intermittent signal or power interruption.

Test the robustness of the mechanical structure and the continued reliability of the electrical contacts.

Design key: Optimized spring design, precise fit tolerances, and reliable retention structures are the foundation of vibration shock resistance.

Grease:

Accidental Contamination: An often overlooked but highly detrimental factor is grease contamination. If a spring-loaded pin connector accidentally comes into contact with grease, silicone oil, or other oily substances during storage, assembly, or maintenance, it can have a fatal effect.

Fatal Effects: Grease

Form an insulating film on contact surfaces, severely impeding current conduction and significantly increasing contact resistance.

Adsorb dust impurities, accelerating wear or corrosion.

Lead to complete failure of the connector, unable to realize the expected electrical connection function, and become a major obstacle to the reliable operation of equipment. Therefore, the production, storage and use of links need to be strictly anti-oil pollution.

Conclusion:

The reliability of spring-loaded pin connectors is no accident, but is based on a deep understanding of the harsh environment and a customized design. Temperature, humidity, salt spray, vibration shock, and grease contamination are all potential causes of failure. When selecting and applying spring-loaded pin connectors, engineers must carefully evaluate the characteristics of the target environment, refer to relevant environmental test standards (e.g., temperature rise test, humidity and heat test, salt spray test, vibration shock test), and ensure the cleanliness of manufacturing and use in order to fully utilize their connectivity potential and safeguard the stable operation of electronic devices under various challenges.

Translated with DeepL.com (free version)

Hecon is a professional Pogo Pin connector factory, and has 10 years of senior engineers to provide you with one-on-one design POGO PIN solutions, if you happen to have Consumer Electronics or Smart Wearables and other applications need Pogo Pins, may wish to come to Hecon to find everything possible to get! help