Concave pogo pin connectors contact surface and connector design

Release time:

2025-06-25

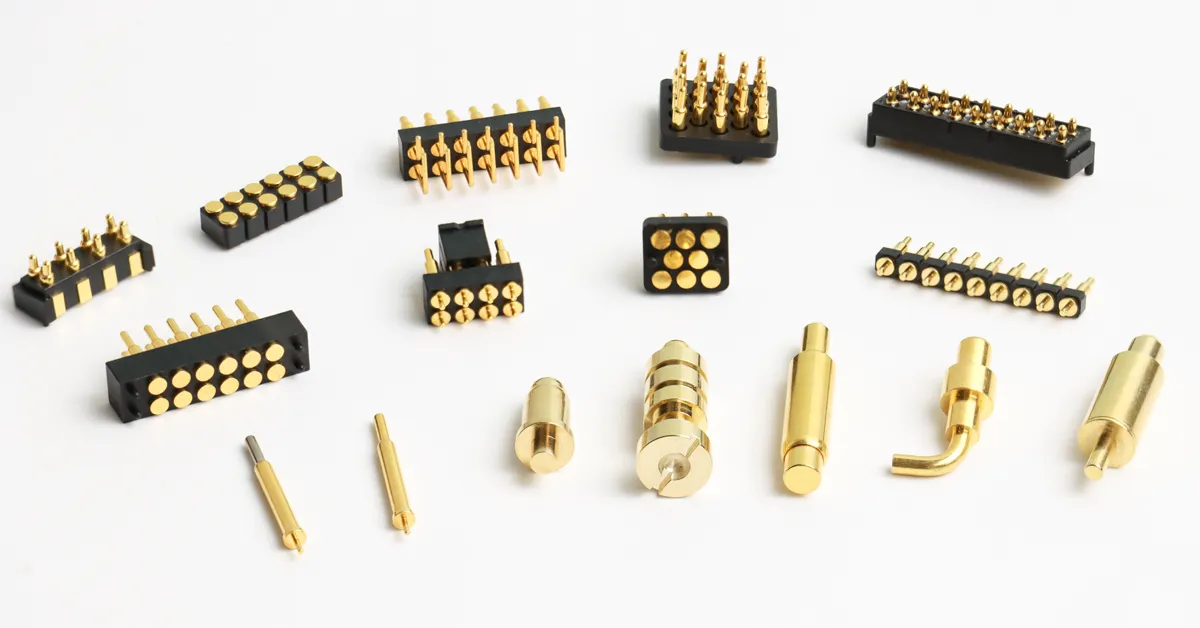

Pogo pins have different shapes at the tip. The concave pogo pin has a tip that curves inward. This shape helps guide the pad into the center. It also stops the pin from moving sideways. This keeps the connection steady. Other tips are flat, dome, or pointed. Each shape works best for certain jobs.

Concave pogo pin contact surfaces are very important in connector design today. Engineers like these surfaces because they help guide connections. They also make alignment better and lower sideways stress on pads. Devices like mobile phones and RF modules use this technology a lot. These devices need to connect and disconnect many times. The concave shape helps signals stay strong and steady. It works well even in tough places or with high-frequency signals. Manufacturers pick concave pogo pin connectors for good electrical performance. They also want connections to stay strong for a long time.

Key Takeaways

- Concave pogo pin connectors help guide pads to the center. This makes alignment better and keeps connections steady. They work well even if there is movement or shaking.

- These connectors last a long time and work in tough places. They use strong materials, gold plating, and flexible springs.

- Concave pogo pins help high-frequency signals move better. They lower resistance and signal loss. This makes them good for mobile phones and communication devices.

- The right pad size and alignment are very important. They make sure contact is strong and keep pins safe from damage.

- Picking concave pogo pin connectors helps devices stay reliable. They can handle many uses and work well in hard conditions.

Concave pogo pin basics

Structure and function

A concave pogo pin is made to give strong electrical connections. It has several main parts. Each part does something important:

| Component | Function |

|---|---|

| Spring | Holds energy and keeps the contact steady, even if surfaces move. |

| Plunger | Moves up and down to touch the device and send signals. |

| Barrel | Holds the inside parts and spreads out the force. |

| Contact Tip | Touches the device and keeps resistance low for good signal flow. |

| Insulating Sleeve | Stops short circuits and keeps electricity in the right path. |

| Base | Attaches the whole pin to the board or device. |

The concave pogo pin often sits on a silicone rubber plate. This plate curves inward. The silicone rubber makes the pin flexible and safe. The pin fits into the curved area. This helps hold it in place. It also protects the connection from bumps or shakes. The matching part on the device is usually convex. When both parts touch, they make a tight seal. This gives a good path for electricity. Designers pick special materials and shapes. This helps the pin work well with high voltage and high frequency.

Contact surface types

Pogo pins have different shapes at the tip. The concave pogo pin has a tip that curves inward. This shape helps guide the pad into the center. It also stops the pin from moving sideways. This keeps the connection steady. Other tips are flat, dome, or pointed. Each shape works best for certain jobs.

Tests show the finish of the contact area is important. Smooth surfaces keep resistance low and steady. Rough surfaces can make tiny metal bits. These bits raise resistance and make the connection weak. The concave design with a smooth finish helps stop these problems. It keeps the connection clean and strong, even after many uses.

Tip: Picking the right contact surface type can help your connector last longer and work better.

Design advantages

Alignment and centering

Concave pogo pin connectors help with alignment and centering. The concave face at the contact surface touches more of the pad. This shape helps guide the pad into the middle of the pin. It makes connections more accurate and steady. Engineers pick this connector for devices that connect and disconnect a lot.

- The concave face gives a bigger area for contact. This helps center the pad when connecting.

- Spring-loaded pins can move a little. They adjust if the pad is not lined up right.

- These connectors can handle small mistakes in assembly or placement. This lowers the chance of damage when connecting.

- The design lets people connect parts without seeing the exact spot. This makes putting things together easier and faster.

- These connectors work well even in tough places. The spring and concave shape help keep the connection strong.

Note: The concave pogo pin design keeps the connection steady, even if devices move or shake. This is very helpful in mobile phones and RF modules, where perfect alignment is hard to get every time.

Durability and reliability

Manufacturers like concave pogo pin connectors because they last long and work well. The strong build and good materials make them great for many uses. Design rules suggest certain pad sizes and hole diameters. This helps the connector work well for a long time. Pogo pins with a concave surface are a good choice instead of regular connectors. They work well under stress and in harsh places.

The gold-plated contact surface stops rust and keeps resistance low. The spring lets the connector work thousands of times without problems. Engineers use concave pogo pin connectors in systems that need to work all the time, like mobile devices and communication gear. These connectors keep a strong electrical contact, even after lots of use. They can handle changes in temperature, shaking, and wetness.

Tip: Picking a concave pogo pin connector can help your device last longer and need less fixing. The design works for high-frequency signals and steady power, so it is a smart pick for hard jobs.

Connector applications

High-frequency signals

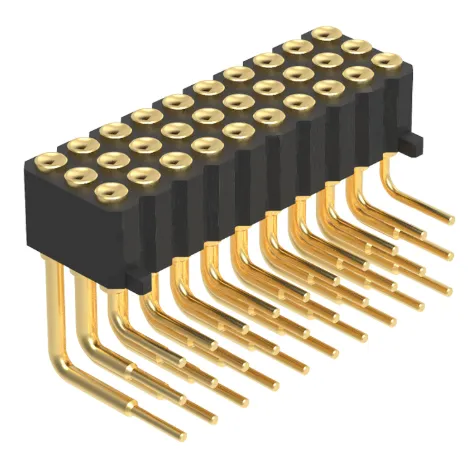

Engineers pick concave pogo pin connectors for high-frequency signals. These connectors help send data in RF, video, and antenna devices. The HECON 2.54mm Pogo Pin Connector has a dual row 2x7 pin SMT design. It also has a concave contact surface. This shape helps guide the pad to the center. It lowers signal loss and makes the connection more reliable.

The table below lists the main technical details for the HECON 2.54mm Pogo Pin Connector:

| Parameter | Value |

|---|---|

| Rated Current | 1A |

| Rated Voltage | 12V |

| Contact Resistance | 30mΩ max |

| Mechanical Life | 100,000 cycles |

| Operating Temperature | -40°C to 105°C |

| Pitch | 2.54mm |

| Pins | Dual row 2x7 pin |

| Contact Surface | Concave spring pogo pin |

| Plating | Gold Flash 3U |

| Working Stroke | 1.0mm (max 1.4mm) |

| Spring Force | 70g ± 20g |

These features help the connector keep low resistance and steady work. It works well even with high-frequency signals. Devices like mobile phones, RF modules, and video gear use these connectors for stable signals. In communication gear, concave pogo pin connectors can send data at 10 Gbps. They keep error rates very low, below 10⁻¹².

Note: High-frequency jobs need good impedance matching and shielding. The concave shape helps keep signals strong by making sure the contact is always tight and lined up.

Harsh environments

Concave pogo pin connectors also work well in tough places. The HECON 2.54mm Pogo Pin Connector uses gold plating and a brass shaft. These parts stop rust and wear. Its PA6T housing and strong spring let it work from -40°C to 105°C. The connector can handle 48 hours of salt spray and solder heat up to 260°C.

- Waterproof magnetic connectors with concave pogo pins pass IP67 tests. They stay dry after 30 minutes underwater at 1 meter.

- Temperature cycling tests show they work from -40°C to +85°C.

- Salt spray tests show no rust after 96 hours.

- Mechanical life tests show over 5,000 plug and unplug cycles with little resistance change.

These features make concave pogo pin connectors great for phones, charging docks, car tests, and robots. The design keeps connections strong when there is shaking, big temperature changes, or water.

Tip: If you need both high-frequency work and toughness, concave pogo pin connectors are a good choice.

Design considerations

Material and plating

Engineers pick materials and plating for pogo pin connectors carefully. The shaft is often made of brass because it is strong and conducts electricity well. Some plungers use beryllium copper or steel. These metals are tough and let electricity flow easily. The housing, like PA6T, can handle heat and keeps the connector stable. This helps protect the connector during soldering and in rough places.

Plating is very important for how the connector works. Gold plating is a thin layer that stops rust and keeps resistance low. Sometimes nickel or hard gold is used to make the connector last longer and slide better. Companies test these materials to make sure they work for many uses. The right mix of base metal and plating keeps the connector working well, even after thousands of uses.

Tip: Gold plating helps the connector carry electricity better and protects it from damage and harsh chemicals.

Pad sizing and alignment

Pads need to be the right size and lined up well for strong connections. The pad should be wide enough for the pin tip and not blocked by solder. Good alignment makes sure each pin touches the right spot on the board. This stops damage to the pins and the device.

The pin’s front end should fit the pad for good contact.

Alignment dowels, about 3-4 mm, go into holes on the PCB. These dowels help guide the board before the pins touch.

Mechanical supports like toggle clamps hold the device steady when connecting.

All pins should get even force. Each pin needs only a little force, but together, it can be a lot.

Seating detection pins in the corners check if the device is fully in place before testing.

Pad surfaces might use HASL or gold plating for better contact. Some pads have solder domes, which need careful stencil work. The shape of the pin head, like concave or domed, changes how well the pin touches the pad and how much it protects it.

Note: Careful pad design and good alignment help stop mistakes and make the connector last longer, even in tough places.

Pogo pin connectors can handle strong shocks and shaking. They keep a steady contact force, so connections stay reliable for many uses. Their modular design makes fixing and adding parts easy. Engineers use these connectors in cars, medical tools, and electronics. This is because they are flexible and last a long time. When picking a connector, teams should think about what the device needs. They should also look at where it will be used and how long it must work. Careful checking helps devices work better and have fewer connection problems.

FAQ

What is a concave pogo pin contact surface?

A concave pogo pin contact surface has a tip that curves inward. This shape helps the pad move to the center. It makes alignment easier and keeps the connection steady. Engineers use this design for better reliability. It works well in devices used many times and with fast signals.

Why do engineers choose gold plating for pogo pins?

Gold plating stops rust and keeps resistance low. This metal lets electricity flow well and helps the connector last longer. Devices that connect and disconnect a lot use gold-plated pogo pins.

How many cycles can a HECON 2.54mm Pogo Pin Connector handle?

The HECON 2.54mm Pogo Pin Connector can be used up to 100,000 times. This makes it good for things that need many connections. Mobile phones and test tools use these connectors often.

Where are concave pogo pin connectors commonly used?

Manufacturers put concave pogo pin connectors in phones, RF modules, antennas, charging docks, and video devices. These connectors give steady signals and strong power in hard places.

What environmental conditions can these connectors withstand?

HECON pogo pin connectors work from -40°C to 105°C. They can handle salt spray for 48 hours and solder heat up to 260°C. This makes them good for tough or changing places.