Introduce the Connection Between Spring Loaded Pogo Pins and Device Performance

Release time:

2025-01-07

Pogo pin

Table of Contents

- 1. Introduction to Spring Loaded Pogo Pins

- 2. What Are Spring Loaded Pogo Pins?

- 3. The Working Principle of Spring Loaded Pogo Pins

- 4. Applications of Spring Loaded Pogo Pins in Devices

- 5. Impact of Pogo Pins on Device Performance

- 6. Benefits of Using Spring Loaded Pogo Pins

- 7. Challenges and Considerations in Pogo Pin Design

- 8. Future Trends in Pogo Pin Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Spring Loaded Pogo Pins

The integration of **spring-loaded pogo pins** in modern devices serves as a cornerstone for enhanced performance and reliability. These components play a crucial role in electronic connections, ensuring that devices operate efficiently across various applications. Understanding the connection between pogo pins and device performance is vital for engineers, manufacturers, and tech enthusiasts alike.

2. What Are Spring Loaded Pogo Pins?

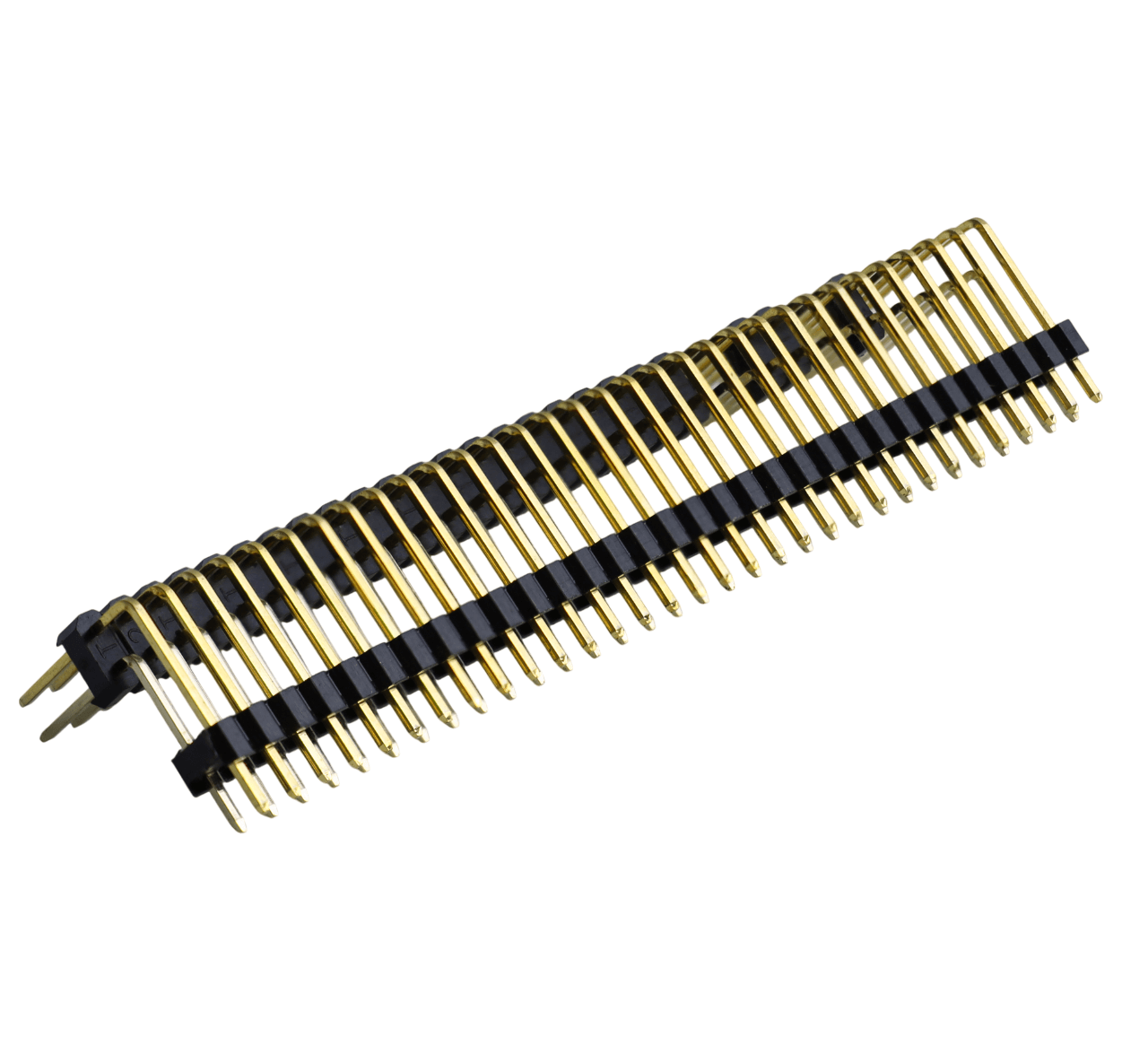

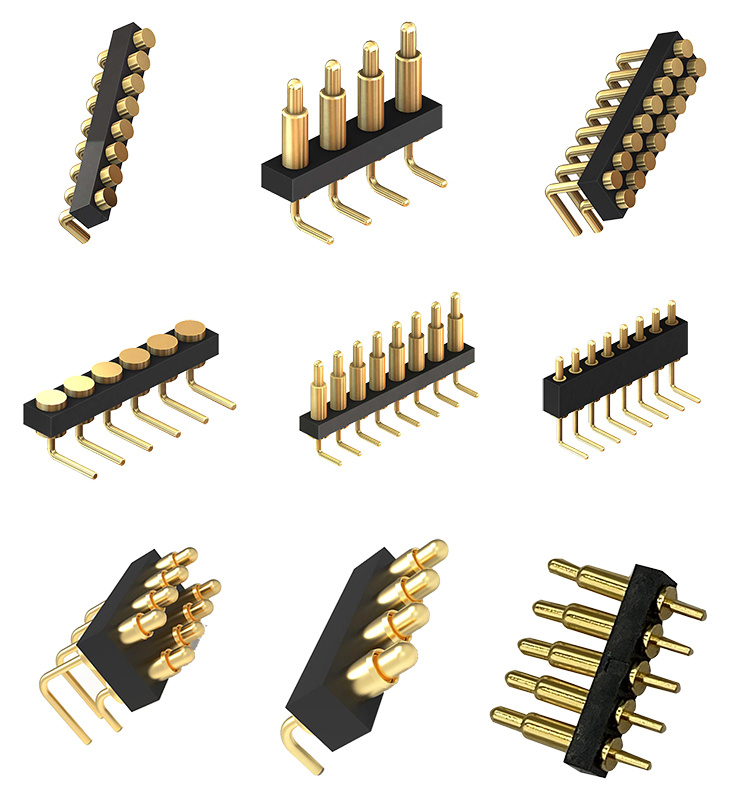

**Spring-loaded pogo pins** are cylindrical conductive pins that are encased in a housing. They feature a spring mechanism that allows the pin to extend and retract, providing a reliable and flexible connection between two surfaces. Typically, these pins consist of a metal shaft with a spring-loaded tip that maintains contact with another conductive surface, ensuring a robust electrical connection.

### H3: Key Features of Pogo Pins

Pogo pins are characterized by several key features that contribute to their effectiveness:

- **Self-Alignment**: The spring mechanism allows for minor misalignments, making it easier to connect with mating surfaces.

- **High Durability**: Designed to withstand repeated use, pogo pins exhibit a long lifespan, which is essential for devices requiring frequent connectivity.

- **Compact Size**: Their small footprint allows for integration into tight spaces, making pogo pins ideal for compact devices.

3. The Working Principle of Spring Loaded Pogo Pins

The functionality of spring-loaded pogo pins is rooted in their **mechanical design**. When a pogo pin is pressed against a surface, the internal spring compresses, allowing the pin to connect with the corresponding conductive area. Once the pressure is removed, the spring expands, pushing the pin back to its original position. This action creates a consistent electrical connection, which is pivotal for device performance.

### H3: Electrical Conductivity and Contact Resistance

The quality of the electrical connection is influenced by several factors, including:

- **Material**: Brass Pogo pins are typically made from high-conductivity metals, such as gold or nickel, which minimize contact resistance.

- **Surface Finish**: A proper surface finish enhances conductivity and reduces wear, ensuring longevity and reliability.

4. Applications of Spring Loaded Pogo Pins in Devices

Spring-loaded pogo pins find applications across a broad spectrum of industries, including:

### H3: Consumer Electronics

In consumer electronics, pogo pins are often used in devices such as smartphones, tablets, and wearables. They facilitate connections for charging, data transfer, and even button functionalities.

### H3: Industrial Equipment

In industrial settings, pogo pins are critical for connecting circuit boards and other components inside machinery. Their robust design withstands harsh conditions, ensuring operational reliability.

### H3: Medical Devices

Medical devices require precise and reliable connections for performance and safety. Pogo pins are often used in diagnostic equipment, surgical instruments, and wearable health monitors.

### H3: Automotive Applications

In the automotive industry, pogo pins are used in various applications, including connecting sensors, modules, and electronic control units. Their ability to maintain reliable connections is crucial for vehicle safety and performance.

5. Impact of Pogo Pins on Device Performance

The presence of **spring-loaded pogo pins** significantly enhances device performance by providing:

- **Consistent Connectivity**: Pogo pins ensure a reliable connection, which is essential for data integrity and device functionality.

- **Reduced Downtime**: With their durability, pogo pins contribute to lower maintenance costs and reduced downtime for devices.

- **Efficiency in Design**: Their compact size allows for innovative designs, enabling manufacturers to create sleeker and more functional devices.

### H3: Performance Metrics

Various performance metrics can be assessed to understand the impact of pogo pins:

- **Contact Resistance**: Lower contact resistance leads to improved electrical performance.

- **Mechanical Stability**: The ability of pogo pins to maintain contact under dynamic conditions enhances overall device reliability.

6. Benefits of Using Spring Loaded Pogo Pins

Incorporating pogo pins into device design offers several advantages:

### H3: Enhanced Reliability

The self-alignment feature of pogo pins reduces the likelihood of connection failures, leading to improved reliability in device operation.

### H3: Flexibility in Design

With various configurations and sizes available, pogo pins provide designers with the flexibility to create innovative and compact solutions tailored to specific applications.

### H3: Cost-Effectiveness

The longevity and durability of pogo pins translate into cost savings over time, as manufacturers can reduce replacement and maintenance expenses.

7. Challenges and Considerations in Pogo Pin Design

While spring-loaded pogo pins offer numerous benefits, certain challenges must be addressed during the design process.

### H3: Environmental Factors

Pogo pins may be exposed to dust, moisture, and extreme temperatures, which can affect their performance. Selecting the right materials and coatings can help mitigate these effects.

### H3: Mechanical Wear

Repeated use can lead to mechanical wear and eventual failure of pogo pins. Therefore, it is essential to consider the application's demands and select appropriate pin ratings.

### H3: Alignment Precision

Although pogo pins offer self-alignment, ensuring precise alignment during the design phase can enhance performance and reduce contact resistance.

8. Future Trends in Pogo Pin Technology

As technology continues to advance, the future of pogo pins looks promising.

### H3: Increased Miniaturization

The trend towards smaller and lighter devices will drive the development of more compact pogo pin designs, allowing for integration into even tighter spaces.

### H3: Smart Pogo Pins

The integration of smart technology into pogo pins, such as sensors and signal processing capabilities, could revolutionize their application, enabling enhanced functionality and performance monitoring.

### H3: Sustainable Materials

With growing environmental concerns, the industry may shift towards more sustainable materials in pogo pin manufacturing, emphasizing recyclability and reduced ecological impact.

9. Frequently Asked Questions

### H3: What are the common materials used for pogo pins?

Pogo pins are generally made from high-conductivity metals, such as gold, nickel, or copper, which help to minimize contact resistance.

### H3: Can pogo pins be customized?

Yes, pogo pins can be customized in terms of size, shape, and electrical specifications to suit specific application needs.

### H3: How do I choose the right pogo pin for my application?

Consider factors such as size, electrical specifications, environmental conditions, and mechanical requirements to select the appropriate pogo pin.

### H3: What is the typical lifespan of a pogo pin?

The lifespan of a pogo pin varies based on usage, but high-quality pins can endure thousands of mating cycles without significant wear.

### H3: Are pogo pins suitable for high-frequency applications?

Yes, pogo pins are designed to handle high-frequency signals, making them suitable for various electronic applications.

10. Conclusion

The connection between **spring-loaded pogo pins** and device performance is undeniable. These components play an essential role in ensuring effective connectivity, reliability, and efficiency across various applications. As technology continues to evolve, the development of pogo pins will also advance, addressing current challenges while unlocking new opportunities for innovation. Understanding the intricacies of pogo pins allows manufacturers and designers to make informed decisions that enhance device performance and user experience. Embracing these advancements can lead to the creation of more efficient, reliable, and compact devices that meet the growing demands of today's technology landscape.