Why Choose Spring Loaded Pogo Pins for Your Next Project?

Release time:

2025-02-12

Why Choose Spring Loaded Pogo Pins for Your Next Project?

Introduction to Spring Pogo Pins

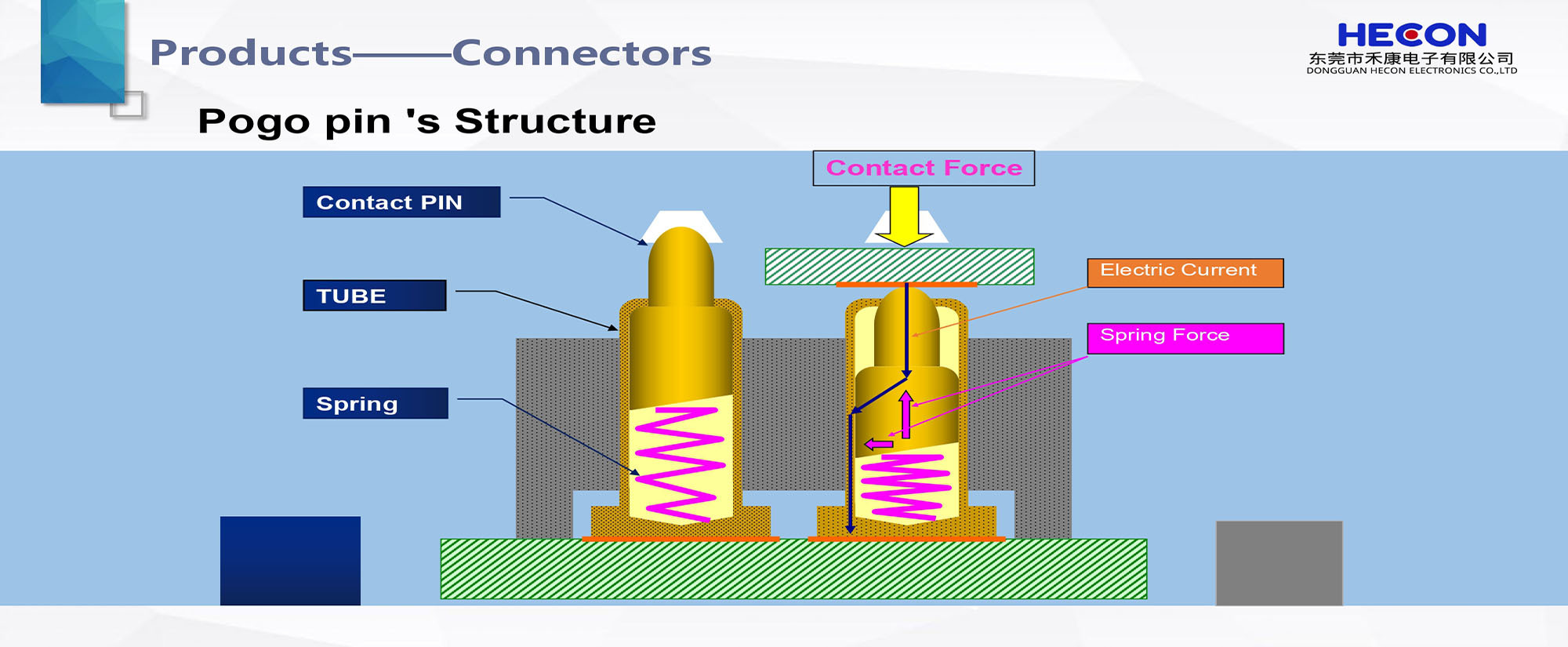

Pogo Pins is a spring-type probe formed by Plunger, Tube and Spring assembly by precision instrument riveter which Its be called Spring pin, Spring thimble, Spring probe, Spring Loaded, Pogo Pins connector. The bottom of a Plunger on a Pogo Pin is usually a sloping structure which is designed to ensure that the plunger keeps the Plunger in contact with the inside wall of the Tube while it is working and allowing the current to flow mainly through the gold-plated plunger and Tube to ensure the stability and low impedance of the Pogo Pins.

What Are Spring Loaded Pogo Pins?

Spring loaded pogo pins are cylindrical electrical connectors that utilize a spring mechanism to establish a secure connection between two surfaces. The structure consists of a pin, a spring, and a housing. When the pin is pressed down, the spring compresses, allowing the pin to connect with the corresponding contact point. This design ensures that the connection remains stable, even in dynamic environments where movement is prevalent.

Advantages of Spring Loaded Pogo Pins

Reliable Electrical Connection

One of the most significant advantages of spring loaded pogo pins is their ability to provide a consistent and reliable electrical connection. The spring mechanism compensates for any misalignment between the pins and their corresponding pads, ensuring continuous contact. This feature is particularly crucial in applications where signal integrity and power distribution are critical.

Self-Alignment Features

Self-alignment is another essential feature of spring loaded pogo pins. This capability allows the pins to adjust themselves when pressure is applied, making it easier to establish connections without requiring precise alignment. This quality is beneficial for manufacturers, as it reduces assembly time and minimizes potential errors during installation.

Space-Saving Design

In a world where space is often at a premium, the compact design of spring loaded pogo pins is a significant advantage. They can be designed to fit into tight spaces without sacrificing performance, making them ideal for a range of applications in consumer electronics, automotive systems, and medical devices.

Applications of Spring Loaded Pogo Pins

The versatility of spring loaded pogo pins allows them to be utilized in various industries. Here are some key applications:

Consumer Electronics

In the consumer electronics sector, spring loaded pogo pins are commonly used in portable devices, charging docks, and connectors. Their ability to provide reliable connections in compact spaces makes them an ideal choice for smartphones, tablets, and wearable technology.

Medical Devices

Medical devices often require reliable and secure connections due to their critical applications. Spring loaded pogo pins are used in diagnostic equipment, sensors, and implantable devices, where patient safety and device performance are of utmost importance.

Industrial Automation

In industrial automation, these connectors facilitate communication between various components, enabling efficient operation and control. Spring loaded pogo pins can be found in robotics, machinery, and instrumentation, where durability and strength are crucial.

How to Choose the Right Spring Loaded Pogo Pins for Your Project

Selecting the right spring loaded pogo pins for your project involves several considerations:

1. **Current Rating**: Determine the current requirements of your application. Pogo pins come in various current ratings, so selecting one that can handle the necessary load is essential.

2. **Stroke Length**: Evaluate the stroke length required for your application. The stroke length affects how much compression the pin can endure, which is vital for maintaining a reliable connection.

3. **Material**: The material of the pogo pin can impact its performance and longevity. Consider factors such as corrosion resistance and conductivity when selecting materials.

4. **Size and Configuration**: Choose the appropriate size and configuration that fits your design specifications. Spring loaded pogo pins come in various sizes and shapes, ensuring compatibility with your project.

5. **Environmental Factors**: Assess the environmental conditions the pogo pins will be exposed to, such as temperature, humidity, and potential contaminants.

By carefully considering these factors, you can ensure that your choice of spring loaded pogo pins aligns with the requirements of your project.

Common Misconceptions About Spring Loaded Pogo Pins

Despite their widespread use, several misconceptions about spring loaded pogo pins persist. Here are a few clarifications:

1. **Limited Lifespan**: Many believe that pogo pins have a limited lifespan due to their mechanical nature. However, when designed properly and used within their specified limits, they can endure hundreds of thousands of cycles.

2. **Only for Low-Current Applications**: While many consider pogo pins suitable only for low-current applications, they are available in configurations that can handle significant currents, making them versatile for various uses.

3. **Difficult to Maintain**: Some users think that pogo pins require extensive maintenance. In reality, they are relatively low maintenance, provided they are kept clean and free from contaminants.

Maintenance and Care of Pogo Pins

To ensure optimal performance, regular maintenance of spring loaded pogo pins is advisable. Here are a few maintenance tips:

1. **Keep Contacts Clean**: Regularly inspect and clean the contacts to prevent oxidation or debris buildup that can affect connectivity.

2. **Avoid Over-Compression**: Ensure that the pogo pins are not subjected to excessive compression beyond their design limits, which can lead to premature wear.

3. **Store Properly**: When not in use, store pogo pins in a clean, dry environment to prevent corrosion and damage.

4. **Check Alignment**: During installation, ensure that the pogo pins align correctly with their corresponding pads to maintain a reliable connection.

By adhering to these maintenance practices, you can extend the life of your pogo pins and enhance their performance.

Conclusion

Spring loaded pogo pins are an invaluable component in various applications, offering reliability, versatility, and durability. Their unique design ensures stable electrical connections while accommodating misalignment, making them particularly suited for industries ranging from consumer electronics to medical devices. By understanding their advantages, applications, and maintenance needs, you can make informed decisions when integrating these connectors into your projects. Choosing the right spring loaded pogo pins can lead to significant improvements in efficiency, reliability, and overall project success.

Frequently Asked Questions (FAQ)

1. What is the primary function of spring loaded pogo pins?

The primary function of spring loaded pogo pins is to provide a reliable electrical connection between two surfaces, accommodating misalignment and ensuring consistent contact.

2. Can spring loaded pogo pins handle high currents?

Yes, spring loaded pogo pins can be designed to handle high currents, making them suitable for various applications requiring significant power transmission.

3. How do I determine the right pogo pin for my application?

To determine the right pogo pin, consider factors like current rating, stroke length, material, size, and environmental conditions relevant to your application. Or you can directly contact Vivien, HECON Sales Manager and provide her with your requirements and we will provide you with a Pogo Pins solution that works with you.

4. Are spring loaded pogo pins easy to maintain?

Yes, spring loaded pogo pins are relatively low maintenance. Regular cleaning and proper storage can significantly extend their lifespan.

5. What industries commonly use spring loaded pogo pins?

Spring loaded pogo pins are widely used in consumer electronics, medical devices, industrial automation, automotive systems, and various other sectors that require reliable connections.

By leveraging the benefits and understanding the nuances of spring loaded pogo pins, we position ourselves to make informed and strategic choices for our next project.