HECON introduces three new injection molding machines, setting a new benchmark for precision manufacturing in the wire harness industry

Release time:

2025-08-01

Low-pressure injection molding technology breakthrough brings revolutionary packaging technology to electronic wire harnesses

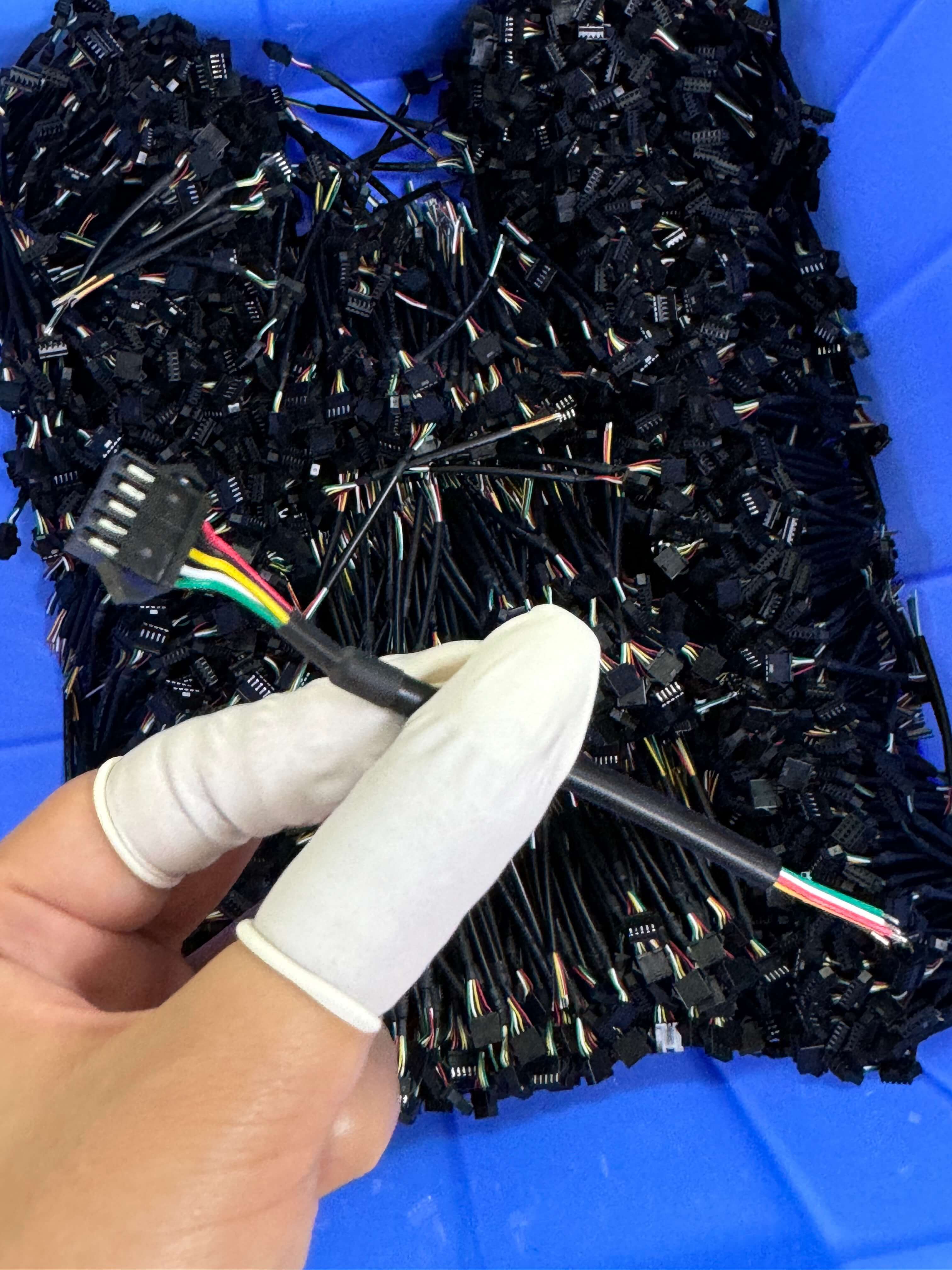

HECON Electronics Co., Ltd. in Dongguan recently announced the completion of the introduction and commissioning of three new injection molding machines, officially putting them into production for wire harness manufacturing. This significant technological upgrade marks a breakthrough for HECON in the field of precision electronic wire harness manufacturing.

The three injection molding machines introduced this time include single-station, dual-station, and pressure-boosting models, which can meet the diverse wire harness production needs of customers from standard to special, providing high-end connection solutions for automotive electronics, medical equipment, and consumer electronics.

Low-pressure injection molding process, synergistic advantages of the three devices.

Low-pressure injection molding is rapidly becoming a key technology in the field of precision electronic packaging.

The three injection molding machines introduced by HECON all use 1.5-50 Bar ultra-low pressure injection molding technology, avoiding damage to precision electronic components while achieving a rapid curing and molding cycle of only 3-60 seconds.

The biggest difference between traditional injection molding and low-pressure injection molding lies in the precise control of temperature and pressure. The new equipment is equipped with an intelligent temperature control system, and through the design of electromagnetic blocks and hoop structures, the heating and cooling tubes can quickly preheat or cool the injection barrel.

This technological breakthrough solves the two major industry pain points of low processing efficiency and slow output in traditional processes. The collaborative operation of the three devices allows HECON to flexibly choose top injection or side injection methods according to product characteristics, meeting the production needs of wire harnesses with different structures.

The combination of single-station and dual-station equipment optimizes production efficiency, while the pressure-boosting injection molding machine is specifically designed to handle high-complexity wire harness packaging tasks, ensuring perfect packaging of precision components through enhanced clamping force.

From waterproof connections to automotive wire harnesses, how injection molding technology reshapes wire harness products

The commissioning of the new injection molding machines has brought a qualitative leap to HECON's wire harness products. In the field of cable injection molding, the core value of the equipment lies in creating connection products with multifunctional protective characteristics.

Through precise mold design and low-pressure injection molding technology, HECON can now produce high-end wire harnesses with eight protective characteristics: insulation, temperature resistance, impact resistance, vibration damping, moisture resistance, waterproofness, dustproofness, and chemical corrosion resistance.

These characteristics are particularly important for automotive electronics. In harsh environments such as engine compartments, traditional wire harnesses are susceptible to temperature, oil stains, and vibrations, while the new injection-molded wire harness products ensure stable operation of the connectors in the temperature range of -40℃ to 150℃ through overall encapsulation technology.

Medical device wire harnesses also benefit from this technological upgrade. The medical-grade wire harnesses produced by the new equipment meet biocompatibility requirements, with no residue left on the surface, avoiding the risk of bacterial growth.

Technology empowers customers, the birth of customized solutions

HECON's equipment upgrade is essentially an upgrade in service capabilities. The flexible production line built by the three injection molding machines makes small-batch customized production economically feasible.

In terms of temperature control component technology innovation, HECON uses a dynamic temperature control system. This system uses electromagnetic blocks and slide structures to allow the heating/cooling units to rotate and adjust along the surface of the injection barrel, achieving uniform temperature control.

This innovation solves the industry problem of local heating or cooling in traditional equipment, significantly improving product consistency. Combined with the automatic polishing system equipped with the equipment, removing residues from the cable surface online, the product cleanliness reaches medical and food-grade application standards.

The HECON engineering team has developed a modular mold system that can quickly switch production of differentiated products such as waterproof connectors, sensor packaging wire harnesses, and automotive electronic wire harnesses according to customer needs.

This flexible production method shortens the customer's new product development cycle by about 40%, helping customers gain a competitive edge in the fierce market competition.

From automobiles to medical devices, the vast world of injection-molded wire harnesses

As electronic devices move towards miniaturization and high integration, the application scenarios of injection-molded wire harnesses are accelerating. Wire harness products produced by HECON's new injection molding machines have successfully entered three cutting-edge fields.

In the new energy vehicle market, the demand for high-voltage connectors and battery wire harnesses is surging. Injection molding technology can encapsulate multiple wires and signal lines at one time, meeting the safety requirements of electric vehicles for high-voltage and high-current connections.

The medical device field also urgently needs miniaturized wire harnesses. The new injection molding machine can precisely encapsulate micro-switch connection wire harnesses with a diameter of 0.3mm, providing key connection components for endoscopes and wearable medical devices.

The smart home field is experiencing explosive growth. HECON has provided waterproof sensor wire harnesses for many leading companies, used in smart bathrooms, outdoor monitoring, and other scenarios.

With the popularization of 5G and Internet of Things technology, the demand for injection-molded wire harnesses in the industrial connector market continues to rise. Data from the 2025 Dongguan International Connector Exhibition shows that the global annual growth rate of industrial connectors is stable at around 8.5%.

HECON is actively deploying this market, and 30% of its new injection molding machine capacity has been planned for the production of industrial-grade waterproof connectors.

HECON has built an industry-leading precision wire harness manufacturing system through the strategic deployment of three new injection molding machines. The dual-station low-pressure injection molding machine significantly improves production efficiency, the pressure-boosting model meets the needs of complex structure packaging, and the intelligent temperature control system ensures zero defects in products.

Wire harness products produced by these advanced equipment have been successfully applied to many new energy vehicle companies, solving the industry problem of high-voltage wire harness sealing; in the medical device field, the aseptic connection wire harnesses produced by the new production line have passed biocompatibility tests and are about to enter the operating room.

In the next three years, HECON plans to expand its injection molding production line to a multi-unit scale, comprehensively covering the connection needs of high-end manufacturing fields from consumer electronics to aerospace.

The traditional industry of wire harness manufacturing is being reborn under the drive of technological innovation.