Understanding Spring Loaded Pogo Pins: An Essential Component in Mechanical Manufacturing

Release time:

2025-04-21

Spring loaded pogo pins are specialized electrical connectors widely utilized in various industries, particularly in manufacturing and mechanical applications. These pins are designed to establish temporary connections between two circuits or components, making them essential for devices that require frequent assembly and disassembly. The unique design of spring loaded pogo pins incorporates a spr

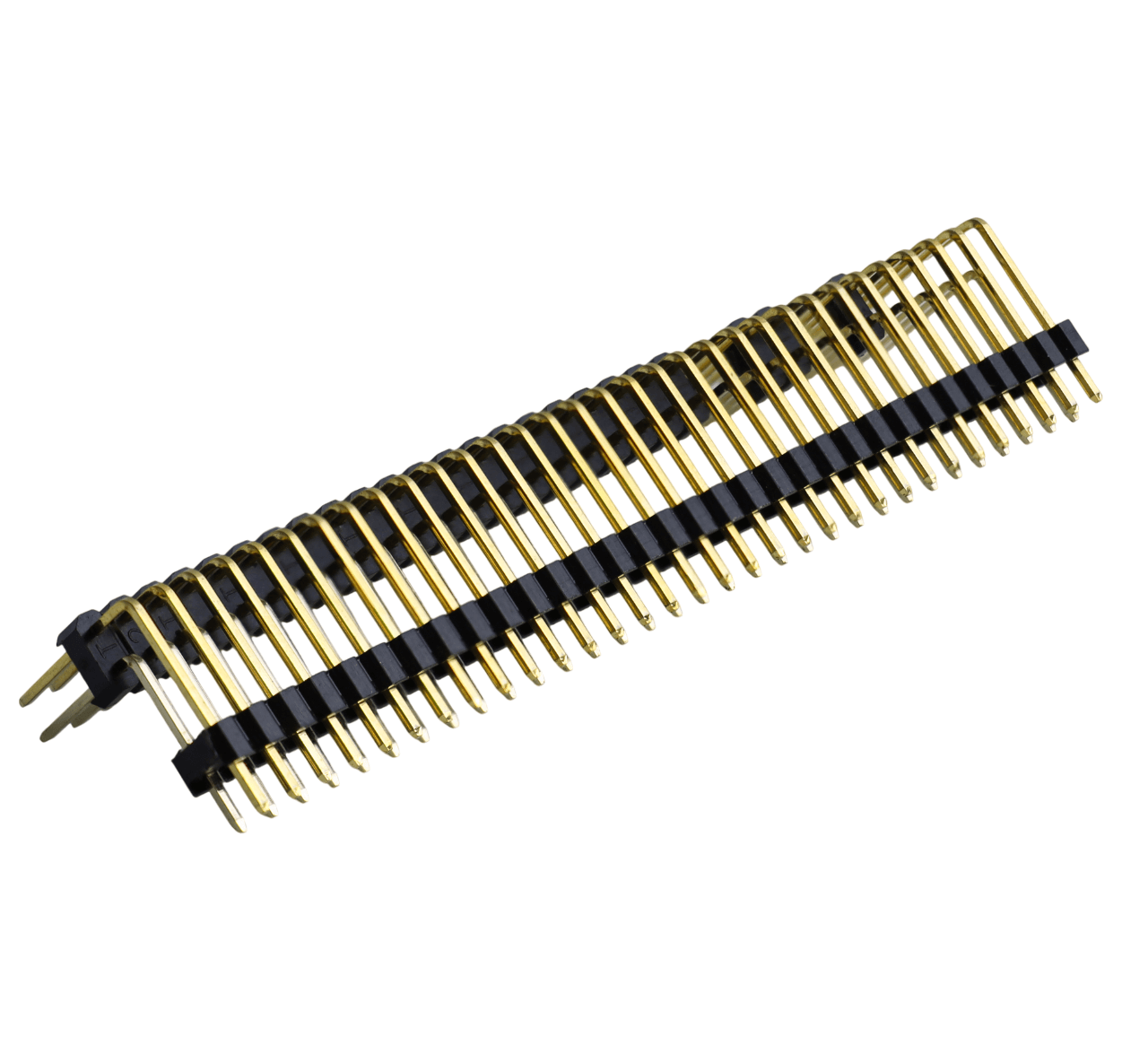

Spring loaded pogo pins are specialized electrical connectors widely utilized in various industries, particularly in manufacturing and mechanical applications. These pins are designed to establish temporary connections between two circuits or components, making them essential for devices that require frequent assembly and disassembly. The unique design of spring loaded pogo pins incorporates a spring mechanism that allows the pin to compress and extend, ensuring reliable contact even in situations where misalignment may occur.

One of the primary advantages of spring loaded pogo pins is their ability to provide consistent and stable connections. In many applications, such as testing devices, consumer electronics, and automotive systems, a reliable electrical connection is crucial for performance. The spring-loaded mechanism compensates for tolerances in alignment, ensuring that the pins maintain contact under varying conditions. This feature is especially beneficial in applications that involve vibration or movement, where traditional connectors may fail to maintain their integrity.

In terms of design, spring loaded pogo pins come in various sizes and configurations to suit specific needs. The selection of a pogo pin typically depends on factors such as the intended application, the required electrical current, and the environmental conditions in which the device will operate. Manufacturers often offer customization options, allowing clients to specify the length, diameter, and spring force of the pogo pins to meet their unique requirements.

Another noteworthy aspect of spring loaded pogo pins is their ease of integration into existing systems. They can be mounted on printed circuit boards (PCBs) or used in conjunction with sockets and housings, making them versatile options for many designs. Their simple installation process reduces assembly time and costs, which is a critical consideration in the competitive landscape of manufacturing.

Moreover, the durability of spring loaded pogo pins contributes to their appeal. These components are designed to withstand repeated cycles of compression and extension, making them suitable for high-cycle applications. When properly implemented, pogo pins can significantly enhance the longevity of devices and reduce maintenance needs, ultimately leading to cost savings over time.

In conclusion, spring loaded pogo pins are essential components in the manufacturing and mechanical sectors, providing reliable electrical connections and adaptability for various applications. Their unique design, durability, and ease of integration make them a preferred choice for engineers and manufacturers aiming to optimize their products and processes. Understanding the functionality and benefits of these components is crucial for making informed decisions in product development and design.

One of the primary advantages of spring loaded pogo pins is their ability to provide consistent and stable connections. In many applications, such as testing devices, consumer electronics, and automotive systems, a reliable electrical connection is crucial for performance. The spring-loaded mechanism compensates for tolerances in alignment, ensuring that the pins maintain contact under varying conditions. This feature is especially beneficial in applications that involve vibration or movement, where traditional connectors may fail to maintain their integrity.

In terms of design, spring loaded pogo pins come in various sizes and configurations to suit specific needs. The selection of a pogo pin typically depends on factors such as the intended application, the required electrical current, and the environmental conditions in which the device will operate. Manufacturers often offer customization options, allowing clients to specify the length, diameter, and spring force of the pogo pins to meet their unique requirements.

Another noteworthy aspect of spring loaded pogo pins is their ease of integration into existing systems. They can be mounted on printed circuit boards (PCBs) or used in conjunction with sockets and housings, making them versatile options for many designs. Their simple installation process reduces assembly time and costs, which is a critical consideration in the competitive landscape of manufacturing.

Moreover, the durability of spring loaded pogo pins contributes to their appeal. These components are designed to withstand repeated cycles of compression and extension, making them suitable for high-cycle applications. When properly implemented, pogo pins can significantly enhance the longevity of devices and reduce maintenance needs, ultimately leading to cost savings over time.

In conclusion, spring loaded pogo pins are essential components in the manufacturing and mechanical sectors, providing reliable electrical connections and adaptability for various applications. Their unique design, durability, and ease of integration make them a preferred choice for engineers and manufacturers aiming to optimize their products and processes. Understanding the functionality and benefits of these components is crucial for making informed decisions in product development and design.