How to customize the consumer electronics wire harness?

Release time:

2025-07-10

Professional Customized Wire Harness & Cable Assemblies

How to customize the consumer electronics wiring?

By using UL-certified cables, one can avoid purchasing cables with substandard performance. By adopting the commonly used models on the market, the development cycle, sample and pilot production costs can be significantly reduced.

Compliant with UL785 (Home Appliance Wiring Standard) such as: UL1007 (Electrical Wire), UL1015 (Electrical Wire), UL2468 (Flat ribbon wire).

After choosing the cable type, the appropriate AWG will be selected based on the size of the housing.

Wire material standards:

UL1007 Rated Voltage: 300V, Rated Temperature: 80°C

UL1015 Rated Voltage: 600V, Rated Temperature: 105°C

UL2468 Rated Voltage: 300V, Rated Temperature: 80°C

Cost of wire harness processing:

UL2468 processing cost

The processing efficiency of the ribbon cable is higher than that of the electronic wire, thereby achieving a cost-saving effect.

Anti-interference process:

The wire-wound ferrite magnetic ring component resists high-frequency interference.

2. Anti-interference treatment of twisted wire pairs

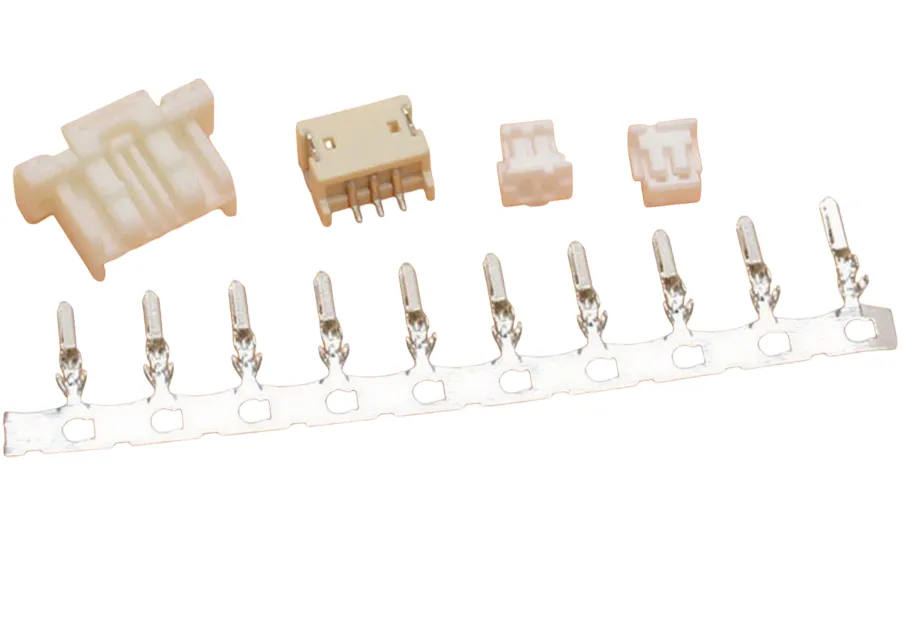

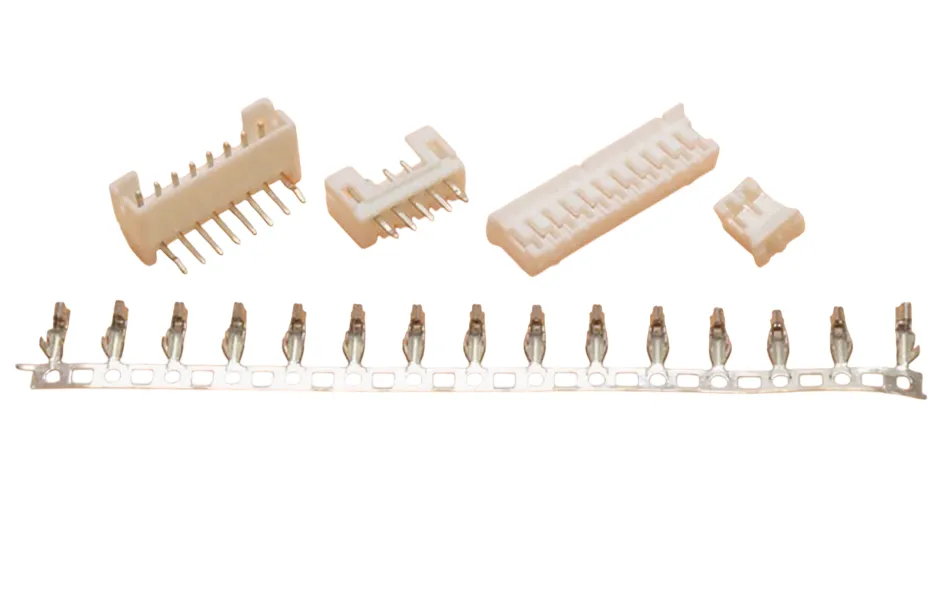

II. How to Choose Connectors

According to the requirements of international cables, HECON suggests choosing the type with a relatively large stock available on the market to reduce the time for sample production and mass production.

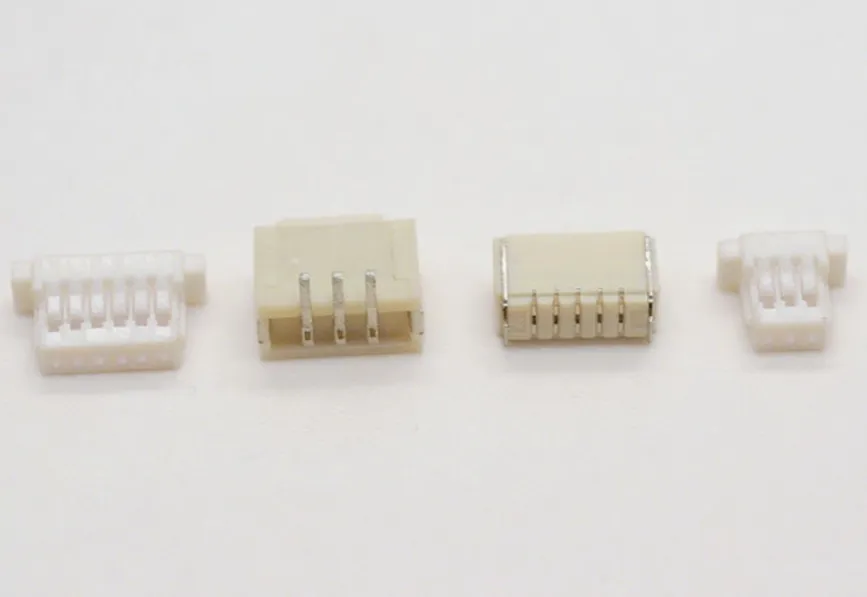

2. Select the appropriate type based on the usage scenario: regular, ultra-thin (to save space), or with a snap-lock (to enhance retention).

Cables Types and specifications:

1.0mm pitch:

SH1.0mm (Standard, Current: 1A, Voltage: 50V)

NH1.0mm (with snap-on cover, current: 1A, voltage: 50V)

SHL1.0mm (Ultra-thin, Current: 1A, Voltage: 50V)

1.25mm ptich:

51021 (Standard, Current: 1A, Voltage: 125V)

51146 (Ultra-thin, Current: 1A, Voltage: 125V)

GH1.25 (with lock, current: 1A, voltage: 125V)

1.5mm pitch:

ZH1.5 (Standard, current 1A, voltage within 100V, open circuit allowed)

87439 (Standard, Current 3A, Voltage 250V)

2.0mm pitch:

PH2.0 (Standard, 2A current, 100V voltage)

PHB2.0 (with lock, current 3A, voltage within 250V)

PA2.0 (Adding guide grooves and locking mechanisms on the basis of PH, current: 3A, voltage: within 250V)

2.5mm pitch:

XH2.5 (Standard, Current: 3A, Voltage: 250V or below)

XHB2.5 (with lock, current: 3A, voltage: 250V or less)

XA2.5 (Based on XH, it is equipped with guide grooves and locking mechanisms. Current: 3A, Voltage: within 250V)

Board-to-board connector series:

1.25mm pitch: 51022 (Current 1A, Voltage 125V)

1.5mm pitch: JZ15 (vertical type, current 1A, voltage 200V), SZN1.5 (horizontal type, current 1A, voltage 200V)

2.0mm pitch: SAN2.0 (vertical type, current 2A, voltage 250V), JB20 (horizontal type, current 2A, voltage 250V)

2.5mm pitch: SCN2.5 (vertical type, current 3A, voltage 250V), JC25 (horizontal type, current 3A, voltage 250V)

3.96mm pitch: SDN (vertical type, current 7A, voltage 250V), JE40 (vertical type, current 7A, voltage 300V)

- Deep Requirements Understanding: We don't just manufacture, we understand your equipment's functionality, operating environment, electrical requirements and space constraints, and work together to define the optimal solution.

- Flexible and Agile Response: We support small batch trial production, emergency orders, special specifications, we provide flexible production mode, rapid response to your customized needs.

- Engineering and Manufacturing Strength: We have advanced production equipment, strict quality control process (from raw materials to finished products) and senior technical team to ensure that each customized wiring harness is accurate, reliable and durable.

- We have a wide range of connectors, terminals and wires to meet your diversified requirements for interface, shielding, temperature resistance, flame retardant and other characteristics.

- Service: Design support, free sample, mass production, 100% rigorous testing, on-time delivery.