At Hecon you can obtain any Pogo Pins solution

Release time:

2025-09-16

You use custom pogo pin connectors all the time. You might not even notice them. They help power smart watches and Bluetooth headsets. They also work in AR/VR devices. These connectors have many good points:

At Hecon you can obtain any Pogo Pins solution

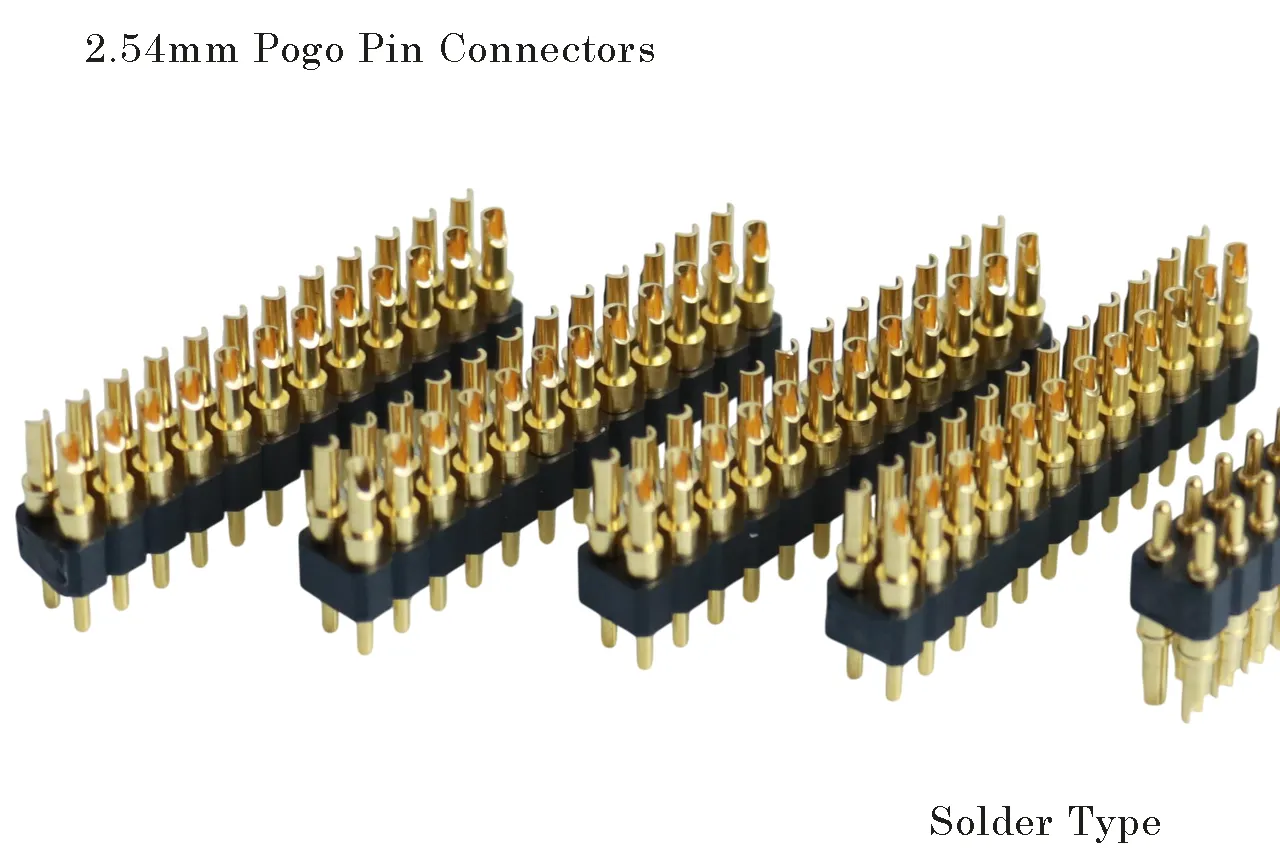

Custom pogo pin connectors help your devices connect with electricity. These connectors can change to fit what you need. You can pick how many pogo pins or how strong the springs are. The global market is growing fast. It is worth $1.2 billion now. It may reach $2.3 billion by 2034. Many industries use custom pogo pin connectors. Medical and car companies need them for power, data, and signals.

| Customization Aspect | Description |

|---|---|

| Number of pogo pins in an array | Changes based on what the device needs. |

| Pitch | The space between pogo pins can be changed. |

| Overall form factor | Made to fit special shapes of cases. |

| Current rating | Changed to match power needs. |

| Specific spring forces | Set for different uses. |

Key Takeaways

Custom pogo pin connectors let you change the design. You can pick how many pins you want. You can also choose the spring strength and size. This helps the connector fit your device better.

These connectors work very well. They have low contact resistance. This means they send strong signals. They are reliable in many uses. People use them in electronics and medical devices.

Pogo pins are very tough. Some can last over 1,000,000 cycles. This makes them good for long-term use. They work well in hard places.

Picking the right materials is very important. You also need the right specifications. This helps the connector work its best. Think about the current rating. Also, think about the environment when you choose.

Working with a smart supplier is helpful. They give you good connectors. These connectors meet industry standards. They also fit your project needs.

Pogo Pins: Benefits

Performance

You want your devices to be fast and reliable. Pogo Pins help you do this. You can pick how many pins you need. You can also choose pin diameter and contact height. Stroke, spring force, and plating thickness can be changed too. These choices help match the connector to your device. Pogo Pins give high precision and low impedance. This means your device gets a strong, clear signal.

Tip: Pogo Pins work well for high-frequency jobs. They keep signal loss low. Your device works better than with regular connectors.

You can check how custom pogo pin connectors perform using different metrics. Here is a table that shows what to check:

| Metric | Ideal Condition | Environmental Risk |

|---|---|---|

| Contact Resistance | Below 50 mΩ | Gets higher with heat |

| Spring Force | High and steady | Gets weaker in extreme temps |

| Lifespan | 10,000+ cycles | Gets shorter from corrosion |

| Current Capacity | 3-5 A or more | Drops in high heat |

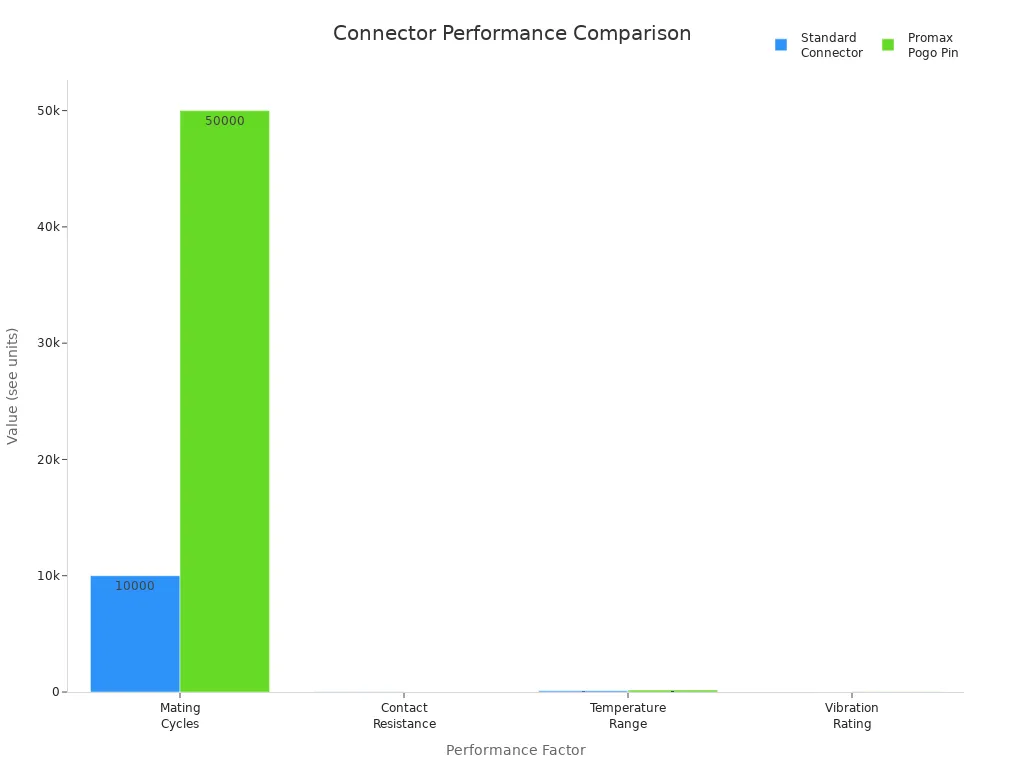

Pogo Pins are special because they keep contact resistance low. They also keep signal integrity high. Regular connectors may lose signal or have interference. Pogo Pins help you avoid these problems.

Flexibility

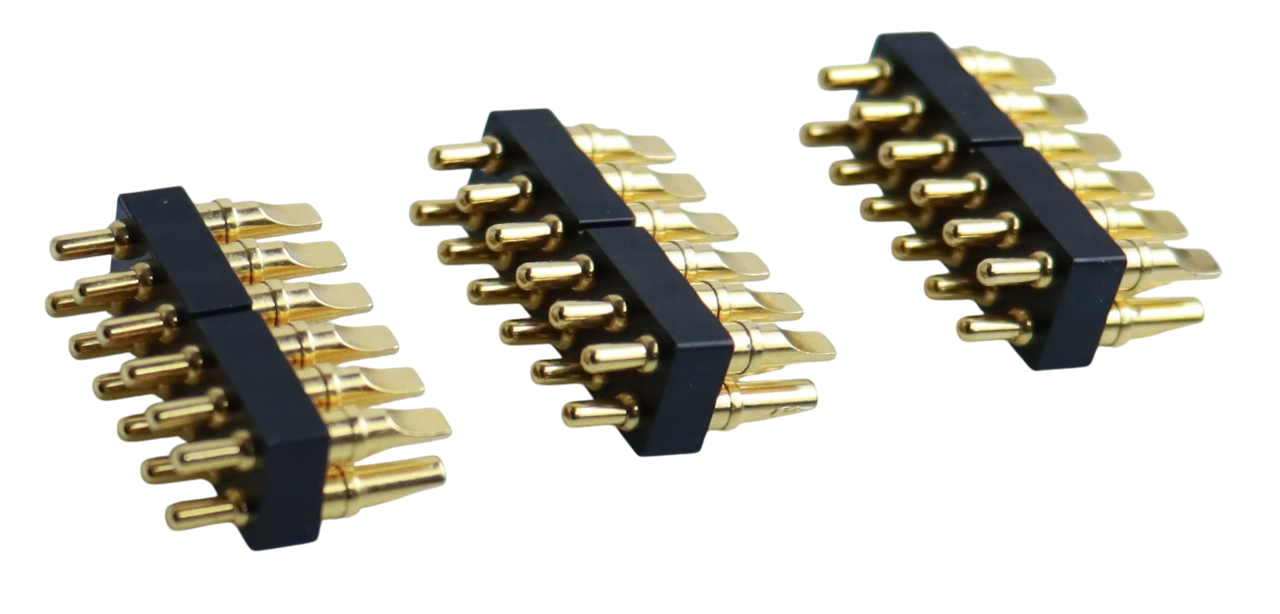

You need connectors that work for many things. Pogo Pins give you this flexibility. You can pick different ways to insert and mount them. The spring contact design lets you connect fast and easy. You can use Pogo Pins for high-density wiring and exact positioning.

High reliability

Quick connection

Precise positioning

High-density wiring

Good adaptability

Customization capability

Pogo Pins can connect by touching a socket. They can also press on a target point on a circuit board. This makes them useful in many devices. You can use them in small gadgets or big machines. Their design helps them work in tough places and special jobs.

Reliability

You want your devices to last a long time. Pogo Pins help you do this. They go through tough tests to make sure they work well. Here are some common tests:

| Testing Standard | Description |

|---|---|

| Accelerated Life Testing | Tests how long pogo pin connectors last under fast conditions. |

| Combined Stress Protocols | Uses many stressors like vibration, temperature, and humidity at once. |

| Application-Specific Trials | Special tests that copy real-life conditions and uses for reliability. |

Pogo Pins can last for thousands of cycles. High precision pogo pin connectors can reach 100,000 cycles. Regular pogo pins last about 50,000 cycles. Some high-performance pogo pins can work for over 1,000,000 cycles. The number of cycles shows how many times you can use the connector before it wears out.

Note: How long Pogo Pins last depends on the materials and how you use them. Good materials and smart design help them last longer.

Applications

Consumer Electronics

You use custom pogo pin connectors all the time. You might not even notice them. They help power smart watches and Bluetooth headsets. They also work in AR/VR devices. These connectors have many good points:

They last for up to 100,000 uses.

Their small size fits tiny gadgets and wearables.

Magnets help line them up easily.

They keep water out for devices with IP ratings.

Custom pogo pin connectors also give you more benefits:

They work well for a long time, even after many uses.

They keep contact pressure steady to stop failures.

Their small size saves space in tiny electronics.

They clean themselves to keep connections strong.

They can be made to fit different devices.

| Application Area | Example Description | Performance Improvement |

|---|---|---|

| Smartphones | Custom connectors make phones work better and smaller. | Over 30% improvement |

Tip: Pogo Pins help your devices work well and stay strong, even as they get smaller and smarter.

Medical Devices

You need medical devices to be safe and work right. Custom pogo pin connectors meet strict rules for these tools. They give you:

Strong connections that last for thousands of uses.

Low contact resistance to keep signals clear.

Small size for portable medical gear.

Safe materials and easy cleaning.

Toughness for hard jobs.

| Standard | Description |

|---|---|

| ISO 13485 | Makes sure medical devices are high quality. |

| ISO 60601-1 | Keeps patients and users safe. |

| ISO 80369 | Stops mix-ups in medical device connections. |

These connectors help things like pacemakers work better than old connectors. They do well even in tricky places.

Industrial

You find custom pogo pin connectors in factories and robots. They connect sensors and robot arms. They also work in test machines. Here are some ways they are used:

| Industry | Applications |

|---|---|

| Industrial Automation & Robotics | Used in robot arms for quick tool changes and strong test jig connections. |

| Internet of Things (IoT) | Make strong links for sensors and smart systems. |

Custom pogo pin connectors help machines run without stopping. They can handle tough places and help robots move just right. This helps machines work longer and better.

Automotive

You want cars to be safe and smart. Custom pogo pin connectors are important in car electronics. They give you:

Strong connections in small spaces.

They carry lots of power and signals.

Their small size fits new car designs.

| Role of Custom Pogo Pin Connectors in Automotive Electronics | Description |

|---|---|

| Reliable Connections | Make strong links in tight spots for car systems. |

| High Current Handling | Good for many car uses. |

| Compact Design | Take the place of old connectors and save space. |

These connectors help smart systems and fun features in cars. They even help with self-driving. They make car electronics faster and last longer.

Design Factors

Configuration

You have many ways to set up your connector. You can pick what fits your device best. The right setup helps it work well and last longer. Check the table below to see what you can change:

| Configuration Aspect | Options Available |

|---|---|

| Size & Format | Lead size, pin diameter, pin format (round, square, rectangular) |

| Contact Material | Brass, copper, nickel, bronze |

| Contact Plating | Gold, silver, nickel, palladium, zinc, tin, lead |

| Electrical Metrics | Contact resistance, current rating |

| Movement | Plunger size, working height, dimensional accuracy (tolerances) |

| Physical Metrics | Initial contact force, mid-compression force |

| Other Factors | Heat, cold, shock, vibration, corrosion, moisture |

| Customization Options | Number of pins, pin diameter, contact height, stroke, spring force, plating thickness, sequence control, mounting options (SMD, Through Hole, Press fit) |

You can pick how many pins you want. You can also choose the pin shape. You can even decide how the pins go on your board. This makes it easy to fit in small or special spaces.

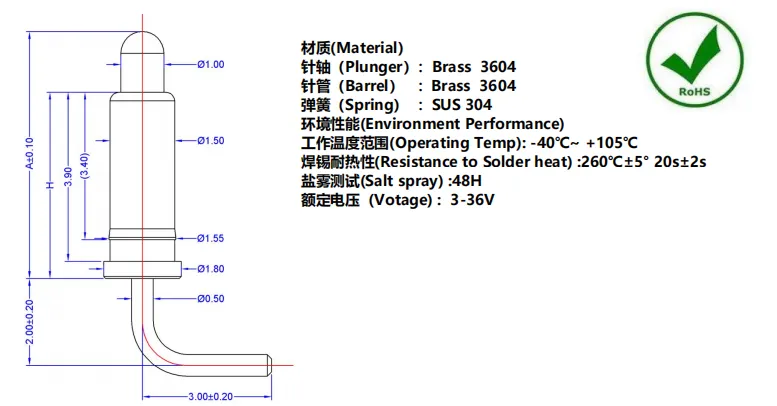

Materials

The materials you use change how well your pogo pin connectors work. Gold over nickel plating keeps the connection strong. It also helps the connector last a long time. For jobs with lots of power, gold and copper alloys are best. They keep the current steady.

| Material Feature | Impact on Lifespan | Industry Fit |

|---|---|---|

| Thick Gold Plating | 100,000+ cycles | Medical & Aerospace |

| Nickel Substrate | Prevents corrosion | Automotive |

| Optimized Spring | Reduces wear | Consumer Electronics |

Beryllium copper or stainless steel can make pogo pins last up to a million cycles. Thick gold plating helps stop rust and makes them stronger.

Tip: Pick your material based on where and how often you use the connector.

Durability

You want your connectors to last a long time. Pick materials that are strong and do not wear out fast. Beryllium copper is good for hard jobs. Stainless steel does not rust in wet places. Nickel-cobalt alloys work well in hot spots.

| Material | Key Properties | Best Use Case |

|---|---|---|

| Beryllium Copper (BeCu) | High strength, good conductivity, fatigue resistance | Industrial automation |

| Stainless Steel Alloys | Excellent corrosion resistance | Wet or chemical environments |

| Nickel-Cobalt Alloys | Strength, corrosion resistance, high temp performance | Extreme heat or stress |

Pins shaped like domes and strong springs help them last longer. Some pogo pins can be used 10,000 times or more. You can add things like weep hole gaskets for extra safety.

Electrical Specs

You need to check some important electrical specs. Rated current, voltage, and contact resistance are key. For fast signals, impedance matching keeps signals clear.

| Specification | Value |

|---|---|

| Rated Current per Pin | ≥0.1A/pin, up to 50A/pin, custom |

| Rated Voltage per Pin | ≥3.0V/pin, up to 550V/pin, custom |

| Contact Resistance (per pin) | ≥10 mΩ per pin, ≤200 mΩ per pin, custom |

| Insulation Resistance | ≥ 1000 MΩ @ 100 V DC |

| Dielectric Withstanding Voltage | 100 V – 500 V AC (between pins) |

| Mechanical Durability (cycles) | 10,000 – 500,000 cycles (custom) |

| High-speed signal transfer | Yes |

Pick stroke length, current rating, and plating for your needs.

Use materials that carry electricity well for steady signals.

Make sure contact force is right for good connections.

Good grounding and shielding help stop signal problems.

Note: The right specs keep your device safe and working, even in hard jobs.

Choosing Pogo Pins

Requirements

Before picking custom pogo pin connectors, you need to know what your project needs. Every job is different and has its own needs. You should look at electrical, mechanical, and environmental things. Think about what materials you want. Also, check how the connector will fit in your device.

Here is a table that shows the main things you should check:

| Requirement Type | Description |

|---|---|

| Electrical Performance | This means current rating, contact resistance, voltage drop, and signal integrity for good connections. |

| Mechanical Durability | This is about cycle life, spring force, and plunger tip shape for long use. |

| Environmental Resilience | This looks at temperature, humidity, and vibration for tough places. |

| Material Compatibility | This means plating, housing, and spring material for strong connectors. |

| Form Factor and Integration | This is about size, mounting, and custom options for your project. |

You should pick a connector that matches your job. Some jobs need special spring forces or different plating. You might need a special way to mount it, like surface mount or through-hole. Pin sizes can change to fit your device. Here is another table to help you see how special needs can change your choice:

| Requirement Type | Description |

|---|---|

| Specific Spring Forces | Picked to match what your job needs for best results. |

| Unique Plating Options | Made for special places like medical or industrial use. |

| Custom Mounting Styles | Choices are SMT, through-hole, right-angle, or cable ends. |

| Specific Pin Dimensions | Picked heights, travel, and diameters for your job. |

Tip: Write down your electrical, mechanical, and environmental needs before you start looking for connectors. This helps you find the best match for your project.

Supplier Evaluation

You want a supplier who knows what you need and can give you good connectors. Start by making a list of what you want. Think about voltage, how many times you will use it, where it will be used, and how big it can be. Good suppliers ask questions about your project and help you find the right answer.

When you compare suppliers, look at these important things:

| Criteria | Description |

|---|---|

| Precision | Makes sure data and power stay steady in different places. |

| Reliability | The connector should work well for a long time. |

| Material Selection | The materials change how well it works and how long it lasts. |

| Testing | Good testing checks contact resistance, strength, and how it handles tough places. |

| Compliance with Standards | Following rules keeps things safe, especially for medical and aerospace. |

You should also see if the supplier knows about high current, long life, and custom jobs. Ask how they test their connectors. Good suppliers check contact resistance, strength, and how well it works in tough places. They follow strict rules for safety and quality.

Note: Suppliers who test well and check quality can help you avoid problems later. Pick a partner who can show you they are experts.

Quality

You want connectors that last and work every time. Quality is very important for custom pogo pin connectors. Look for suppliers who follow strict rules and have important certificates.

Here are some certificates and rules you should check:

RoHS and REACH Compliance: These keep bad stuff out and make products safer.

ISO 9001:2015 Certification: This shows the supplier has a good quality system.

Industry Certifications: IATF 16949 for cars or ISO 13485 for medical devices show they know special jobs.

IPC & J-STD Workmanship Standards: These make sure soldered parts are good and reliable.

Top makers test their connectors before sending them to you. They use different tests to make sure each connector is good. Here is a table that shows common ways to test:

| Testing Method | Purpose |

|---|---|

| Pre-production performance validation | Checks strength and electrical stability before making lots of them. |

| Specialized magnetic testing | Checks magnetic field, polarity, and interference. |

| Production readiness assessments | Makes sure the process is good so there are no problems later. |

| Accelerated life testing | Pretends to use it for a long time to find weak spots. |

Tip: Always ask for test reports and certificates. This helps you make sure your connectors will work well and last a long time.

By checking what you need, looking at suppliers, and caring about quality, you can pick the best custom pogo pin connectors for your project.

Custom pogo pin connectors help you make strong and flexible links. They also last a long time. You should look at some important things before picking one.

| Consideration | Description |

|---|---|

| Quality | Check if the connectors work well and last long. |

| Customization | Pick a supplier who can meet your needs. |

| Cost | Try to get good quality for a fair price. |

| Lead time | Choose a supplier who can send parts on time. |

| Technical support | Find a supplier who helps you fix problems. |

You get better results if you work with skilled makers. Think about what your device needs for strength, power, and the place it will be used.

Tip: If you plan well and pick the right partner, your devices will be safer and smarter.

FAQ

What is a pogo pin connector?

A pogo pin connector uses spring-loaded pins to make electrical contact. You can use it for quick and reliable connections in many devices. The spring keeps the pin pressed against the contact point.

Why should you choose custom pogo pin connectors?

Custom pogo pin connectors let you pick the size, shape, and features you need. You get better performance and a perfect fit for your device. This helps your product work better and last longer.

How do you maintain pogo pin connectors?

You should keep the connectors clean and dry. Use a soft brush or cloth to remove dust. Avoid bending the pins. Regular checks help you spot wear or damage early.

Can pogo pin connectors handle high current?

Yes, you can choose pogo pin connectors designed for high current. Some pins carry up to 50A. Always check the current rating before you use them in your project.

Where do you use pogo pin connectors most often?

You find pogo pin connectors in smart watches, medical devices, robots, and cars. They work well in places where you need fast, strong, and repeated connections.