How to Choose the Right XT90 Wire Harness Cable Assembly Supplier

Release time:

2025-08-30

The optimal solution lies in specialized XT90 Wire Harness Cable Assemblies. These are not standard cables but custom-engineered solutions designed for high-current applications. A professional Wire harness supplier provides assemblies that ensure perfect compatibility with your equipment, superior electrical performance, and robust environmental protection. They transform power connectivity from a weak link into a system strength.

How to Choose the Right XT90 Wire Harness Cable Assembly Supplier

For Australian businesses in electric vehicles, drones, or renewable energy systems, connecting high-current components reliably is a constant challenge. Many face issues with connectors overheating under load, insufficient waterproofing in harsh climates, or compatibility problems with existing systems. These frustrations lead to downtime, safety concerns, and increased maintenance costs, ultimately impacting your bottom line and operational efficiency.

The optimal solution lies in specialized XT90 Wire Harness Cable Assemblies. These are not standard cables but custom-engineered solutions designed for high-current applications. A professional Wire harness supplier provides assemblies that ensure perfect compatibility with your equipment, superior electrical performance, and robust environmental protection. They transform power connectivity from a weak link into a system strength.

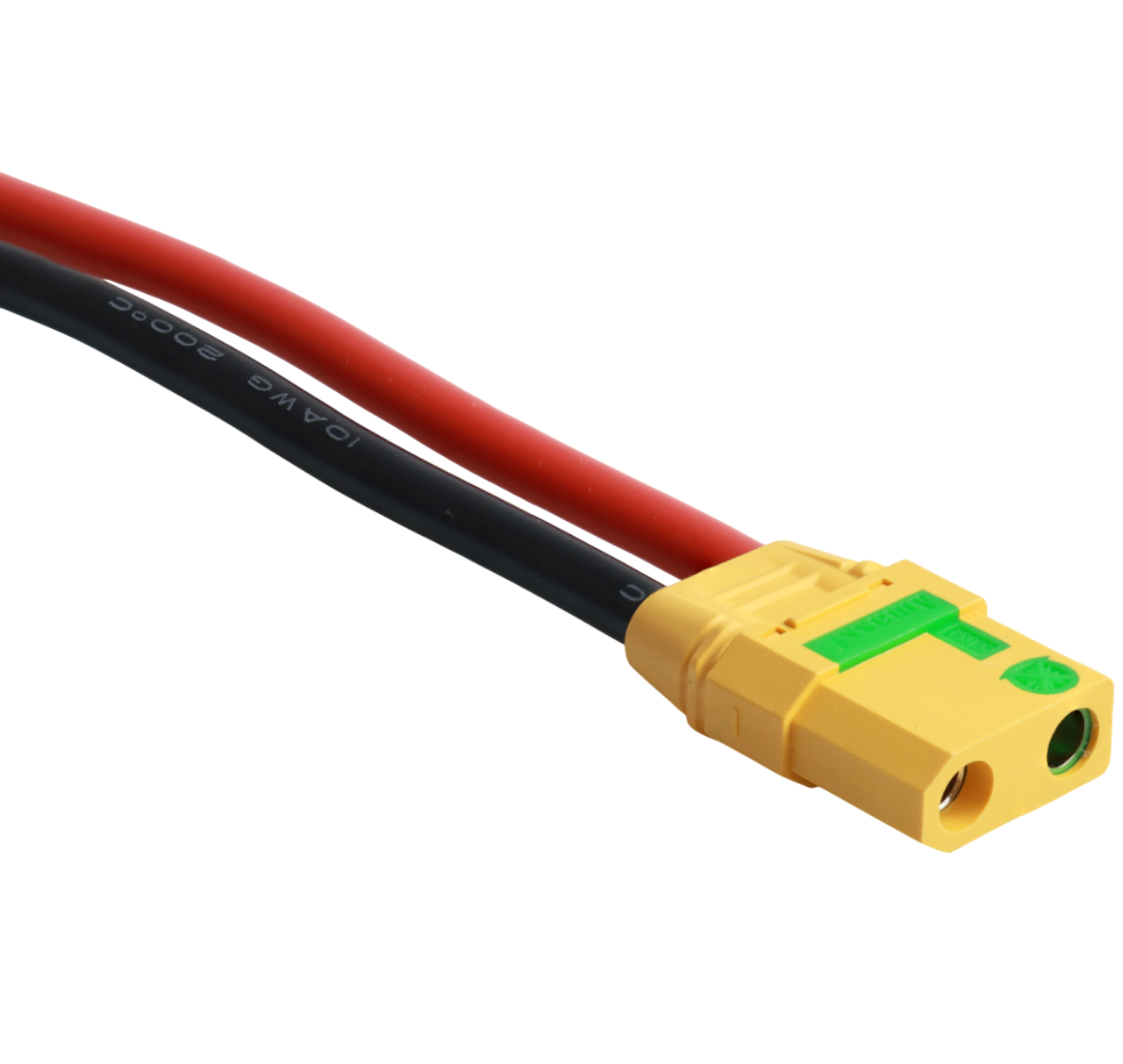

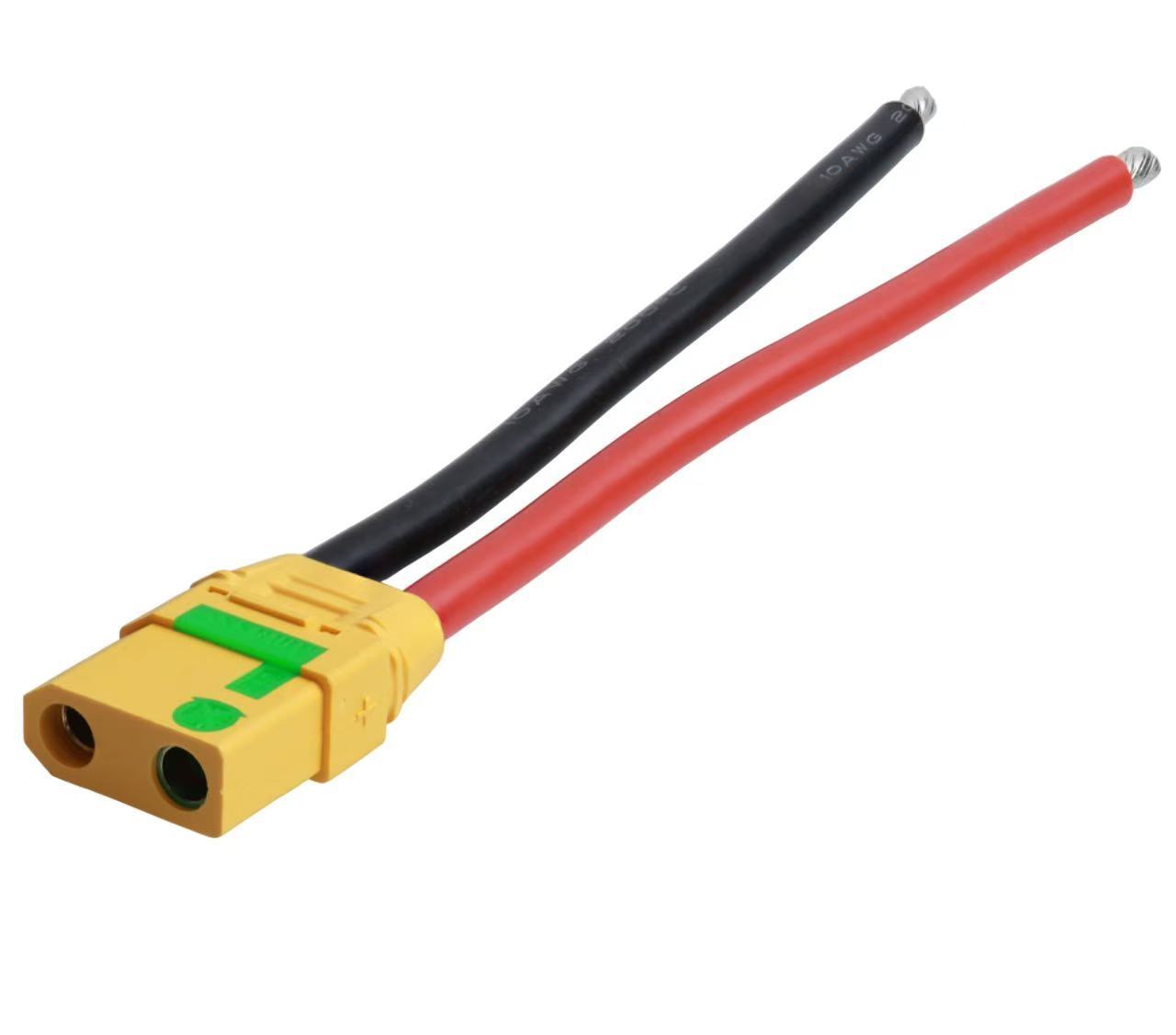

Technical Specifications: What Makes a Quality XT90 Assembly?

When sourcing your XT90 Female Connectors Wire harness cable, scrutinize these technical parameters. High-quality assemblies feature precision-molded XT90 connectors rated for at least 30A continuous current and 60A peak current (like the XT90E-M ), with a voltage rating of 500V. The terminals are typically copper with a gold flash plating for low resistance and corrosion resistance . Look for cables made with 10-12AWG wire to handle the current without excessive voltage drop or heating.

Crucial for Australian conditions is the environmental rating. The best suppliers offer IP67 or IP68 waterproof cable options , ensuring the assembly is completely protected against dust and can withstand temporary immersion (IP67) or prolonged immersion under pressure (IP68). The housing should be made from UL94 V-0 rated flame-retardant materials, such as PBT or polyamide , with a wide operating temperature range of -20°C to 120°C to handle both outback heat and cooler climates.

Why Partner with a Specialist Wire Harness Supplier?

Partnering with a expert Wire harness supplier goes beyond simple procurement. They offer vital Custom services from design to production. This means they can adapt the XT90 Wire harness cable assembly to your exact needs, modifying lengths, wire gauges, connector angles (e.g., straight or 90-degree), and adding protective features like strain relief or shielding.

Reputable suppliers uphold international quality standards, with ISO certification and often IATF 16949 for automotive applications , ensuring every unit meets stringent consistency and reliability requirements. Furthermore, a dependable partner understands the importance of support sample units for your testing and validation phases before full-scale production, mitigating risk and ensuring perfect integration into your products.

Australian Client Success: A Case in Point

Consider an Australian manufacturer of electric mobility scooters. They faced recurring failures with generic power cables connecting their battery packs to motor controllers, especially in coastal areas where salt air accelerated corrosion. The solution was a custom-designed XT90 Wire harness cable assembly from a supplier specializing in robust connectivity.

The supplier provided a pre-production support sample for testing. The final assembly featured XT90 Female Connectors with an IP67 rating to prevent moisture ingress and corrosion-resistant gold-flashed contacts . This high-quality Wire harness cable resolved the failure issues, extended product life, and enhanced customer satisfaction. The supplier's ISO certification guaranteed the consistent quality of every subsequent order, providing the Australian company with a reliable long-term supply chain partner.

Frequently Asked Questions (FAQ)

Q1: Can you provide custom-length XT90 harnesses with specific connector types?

Yes, most specialized suppliers thrive on Custom services. You can get assemblies in any required length, and they can integrate various connector types (not just XT90) into a single harness to simplify your system wiring.

Q2: What is your typical lead time for new orders or samples?

Lead times vary, but for simple modifications, they can be as short as 4-7 days . For completely new designs, it will take longer. Reputable suppliers are transparent about timelines and often expedite support sample requests to accelerate your development cycle.

Q3: Do your products meet Australian safety standards?

A trustworthy supplier will design and manufacture products to meet international safety standards (like UL and IEC). Furthermore, they use materials with relevant certifications (e.g., UL94 V-0 ) and can provide test reports to help you demonstrate compliance with Australian requirements.

Q4: What is the minimum order quantity (MOQ) for custom harnesses?

This depends on the customization level. Many suppliers cater to both low and high-volume needs. Some may offer low or no minimum order quantity for custom cable modifications, making them accessible for prototypes and smaller batches.

Q5: How do you ensure quality control?

Look for a supplier with a certified quality management system, such as ISO certification. This ensures structured processes for incoming material inspection, in-process testing, and final product verification, guaranteeing that every XT90 Wire harness cable assembly you receive performs as expected.